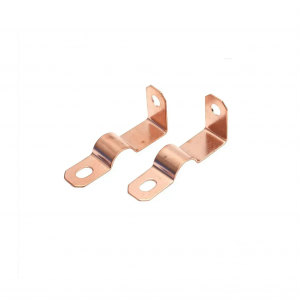

Top door frame – Accessory Z-bracket for door closer

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Metal stamping materials

For both our custom and conventional metal stampings, Xinzhe provides the following materials:

Steel: Cold forming works well with general-purpose CRS steel, such as 1008, 1010, or 1018.

316/316L, 304, and 301 stainless steel are examples. Excellent tensile strength characterizes 301 stainless steel, while significant performance and corrosion resistance at elevated temperatures are found in 304 stainless steel. The most corrosion resistance of the three is found in 316/316L steel, which is also the most expensive.

Copper: this includes C110, an easily formable and potent conductor.

Brass 260 (70/30) and 230 (85/15) are very formable and resistant to corrosion. Red brass and yellow brass are other names for these brass alloys.

Please feel free to ask our specialists about the materials you need, and Xinzhe can stamp various sheet metal materials upon request.

Post-processing options for our stamping materials include bead blasting, powder coating, chem film, anodizing, and electroless nickel, gold, or silver plating.

Why choose us

1. Expert sheet metal fabrication and metal stamping parts for more than a decade.

2. We focus more on maintaining a high standard during production.

3. Outstanding support around-the-clock.

4. Quick turnaround—within a month.

5. Robust technical staff to support and maintain research and development.

6. Invite OEM participation.

7. Satisfied customers with very few complaints.

8. The mechanical properties and durability of every product are good.

9. A competitive and acceptable price.