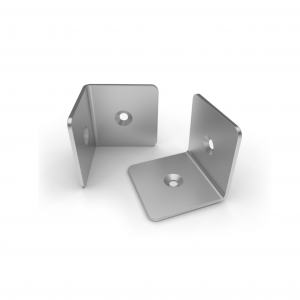

Stamp aluminium sheet metal parts

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Company profile

As one of China's leading suppliers of stamped sheet metal, Ningbo Xinzhe Metal Products Co., Ltd. focuses on producing auto parts, agricultural machinery parts, engineering parts, construction engineering parts, hardware accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tools, toys, and electronic accessories, among other things.

Both parties gain from our ability to more fully comprehend the target market and offer practical recommendations that will assist our clients get a larger market share. We're dedicated to giving our clients outstanding service and premium parts in order to earn their trust. Establish enduring connections with current clients and actively pursue new business in non-partner nations to promote cooperation.

Oxidation process

The following steps are often included in the oxidation process:

1. Raw material feeding: Use pipes to provide the raw materials to the reactor in order to maintain the proper balance of raw materials within.

2. Reaction: To carry out the oxidation reaction, add oxygen to the reactor and regulate the reaction parameters (such as temperature, pressure, and reaction time).

3. Product separation: Use an air cooler to chill the reacted product, turn it from a gaseous state into a liquid or solid form, and then use a separator to separate the products originating from various components.

4. Purification: To ensure that the reaction product reaches the necessary purity, purify it.

5. Packaging: After the products are purified, they are packaged in accordance with guidelines and standards before being either sold to clients or sent on to the next stage of processing.

In some specific applications, such as semiconductor wafer processing, the oxidation process also involves providing oxidants (such as water, oxygen) and thermal energy on the silicon substrate to form a silicon dioxide (SiO2) film. This oxide film protects the wafer by preventing leakage current from flowing between circuits, preventing diffusion during the ion implantation process, and acting as an anti-etching film that prevents mistaken etching during the etching process.