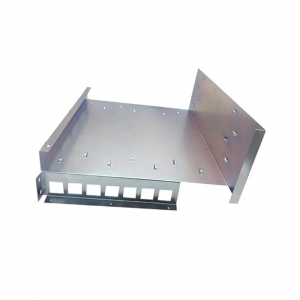

Small stainless steel metal custom sheet metal stamping parts

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Application areas

What equipment are stamped electronic connectors suitable for?

Stamped electronic connector is an electronic connector processed by stamping technology. It has the characteristics of high precision, high efficiency and high reliability, and is suitable for a variety of equipment and industries. Here are some of the main application areas:

1. Automobile industry:

Stamped electronic connectors play an important role in automobile manufacturing and are used to connect various electronic components in automobiles such as batteries, circuit boards, sensors, and motors. They can withstand high temperature, high voltage and high current environments, ensuring the stable operation of automotive electronic systems.

2. Electronic equipment:

It is widely used in electronic products such as mobile phones, tablets, computers, and televisions, and is used to connect various electronic components, such as batteries, metal casings, etc. The use of stamped electronic connectors improves the performance and stability of the device.

3.Household appliances:

In household appliances such as televisions, washing machines, refrigerators, etc., stamped electronic connectors are used to connect and protect circuits to ensure the normal operation and safety of the equipment.

4.Medical devices:

In medical devices such as surgical forceps, syringes, and artificial joints, stamped electronic connectors are used to connect metal parts to improve the durability and functionality of the device.

5. Optical instruments:

In the manufacturing of optical instruments such as lenses, barrels, brackets, etc., stamped electronic connectors are used to connect and control optical components to ensure the accuracy and stability of the equipment. In summary, stamped electronic connectors are used for their high precision, high efficiency and Due to its high reliability, it is widely used in many fields such as the automotive industry, electronic equipment, household appliances, medical equipment and optical instruments.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Bending process

Bending and cutting machines are the major tools used in the manufacturing of bent items. The kind, specifications, and production needs of the workpiece should be taken into consideration when choosing a bending machine. This will guarantee that the machine satisfies processing requirements and is simple to use, fully functional, and easy to maintain. To guarantee the dimensional precision of the cut parts, a front-end cutting machine could be required for large-diameter bent pieces.

FAQ

Q: Are you a trading company or manufacturer?

A: We are manufacturer.

Q: How to get the quote?

A: Please send your drawings (PDF, stp, igs, step...) to us by email , and tell us the material, surface treatment and quantities, then we will make a quotation to you.

Q: Can I order just 1 or 2 pcs for testing?

A: Yes, of course.

Q. Can you produce according to the samples?

A: Yes, we can produce by your samples.

Q: How long is your delivery time?

A: 7~ 15 days, depends on the order quantities and product process.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.