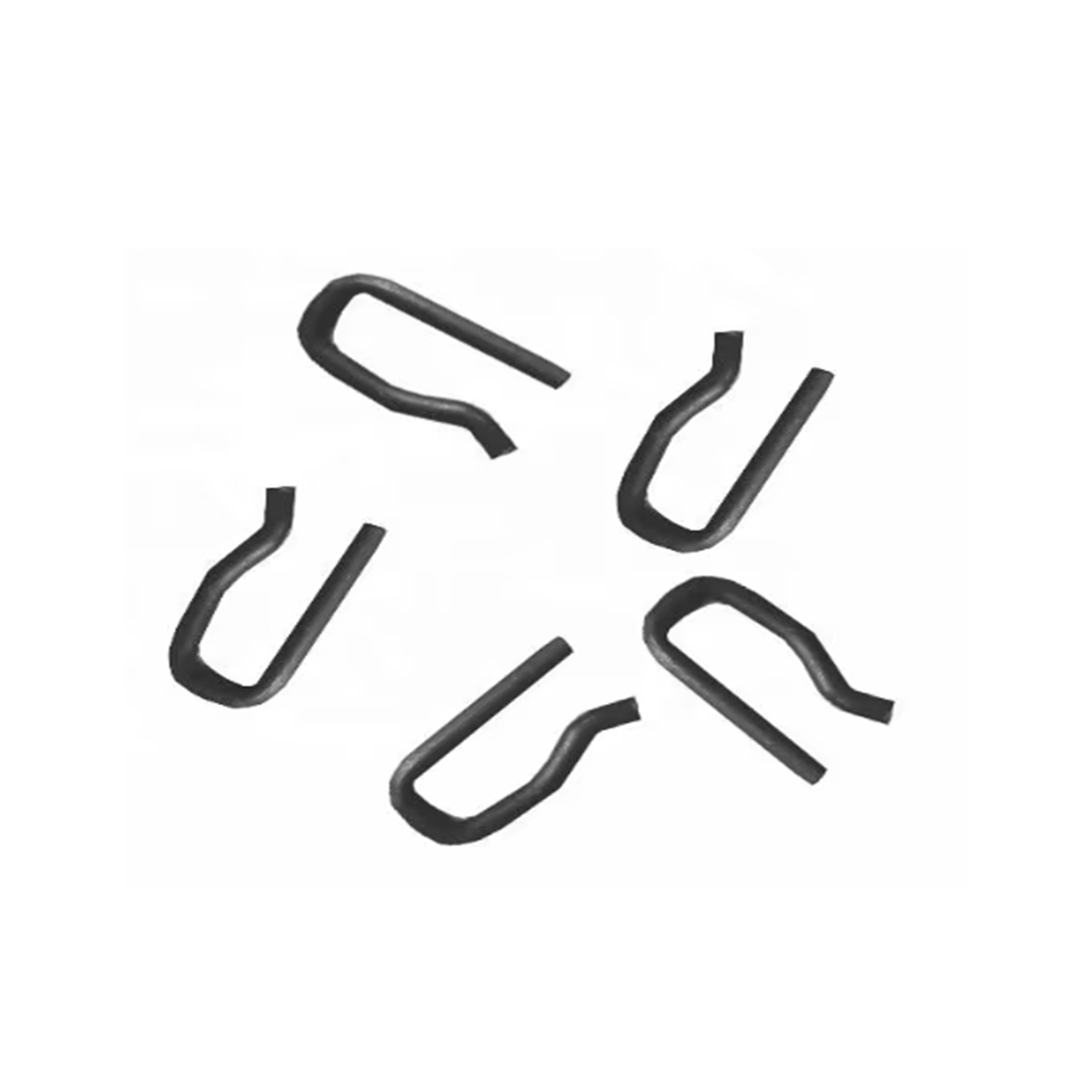

R-type pin step shaft clamp spring escalator accessories

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1.Over a decade of experience in international trade.

2. Offer comprehensive services ranging from mold design to product delivery.

3. Short delivery time—roughly 30 to 40 days. in stock in a week.

4. Strict process control and quality management (ISO-certified factory and manufacturer).

5. More affordable cost.

6. Professional: We have over ten years of experience stamping sheet metal at our facility.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Types of stamping

The manufacturing of escalator step chain circlips is a precise and critical process, and it is necessary to ensure that the quality and performance of the circlips meet the requirements of escalator operation. The following are the general steps for manufacturing escalator step chain circlips:

1. Material selection and preparation:

According to the design requirements of the escalator step chain circlip, select suitable metal materials, such as stainless steel or high-strength alloy steel. Conduct quality inspections on the selected materials to ensure they are free of defects such as cracks and pores and comply with relevant standards and specifications.

2. Mold design and manufacturing:

According to the shape and size requirements of the circlip, a special stamping mold or casting mold is designed and manufactured. The mold should be highly accurate and durable to ensure the manufacturing accuracy and consistency of the circlip.

3. Molding process:

Using a stamping machine or casting equipment, the metal material is placed into the mold, and the basic shape of the circlip is formed by stamping or casting. Ensure that parameters such as temperature, pressure and speed during the molding process are controlled within appropriate ranges to obtain good molding results.

4. Subsequent processing:

The formed circlip is subjected to subsequent processing such as deburring and trimming to ensure that the surface is smooth and defect-free. If necessary, heat treatment or surface treatment can also be performed to improve the hardness and corrosion resistance of the circlip.

5. Quality inspection:

Conduct quality inspection on the manufactured circlips, including dimensional measurement, hardness test, tensile test, etc. Ensure that all performance indicators of the circlip meet the design requirements and relevant standards.

6. Packaging and storage:

Clean and rust-proof qualified circlips, and use appropriate packaging materials for packaging. Store in a dry, ventilated environment to avoid moisture and corrosion.

The manufacturing process for escalator step chain circlips may vary from manufacturer to manufacturer and specific needs. During the actual manufacturing process, detailed manufacturing processes will be formulated based on specific circumstances and relevant manufacturing standards and specifications will be followed. At the same time, we focus on equipment maintenance and operator training to ensure the stability of the manufacturing process and consistency of product quality.

FAQ

Q: Are you a trading company or manufacturer?

A: We are manufacturer.

Q: How to get the quote?

A: Please send your drawings (PDF, stp, igs, step...) to us by email , and tell us the material, surface treatment and quantities, then we will make a quotation to you.

Q: Can I order just 1 or 2 pcs for testing?

A: Yes, of course.

Q. Can you produce according to the samples?

A: Yes, we can produce by your samples.

Q: How long is your delivery time?

A: 7~ 15 days, depends on the order quantities and product process.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.