OEM High Quality Turbine Inlet Gaskets Service – Custom sheet pressed metal cutting parts metal stamping parts – Xinzhe

OEM High Quality Turbine Inlet Gaskets Service – Custom sheet pressed metal cutting parts metal stamping parts – Xinzhe Detail:

Description

Services

Future of Metal Stamping Services

Nowadays, the application of Metal Stamping processing has been very extensive, and it is involved in various industries. It can be said that it is the basis of industrial production, and the future development prospects are broad.

Our company has many years of development history in the Metal Stamping processing service industry. Not only has we mastered the most advanced production experience, but also has a very precise grasp of the industry. We believe that Metal Stamping processing services will establish a complete quality assurance system in the future. Further improve the level of precision, automation, and information manufacturing to meet the needs of mass and flexible production.

In addition, the quality of the Metal Stamping equipment produced will also be further improved, which can be more suitable for some high-end industries. Our company has always worked hard to achieve this goal. We believe that under the premise of adhering to the development of innovation, we can definitely make greater contributions to the Metal Stamping processing service industry!

FAQ

1.Are you a manufacturer or a trading company?

The company has 1200 ㎡of plant area and 18 professional technical workers in ningbo

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG…) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1)Material inspection–Check the material surface and roughly dimension.

(2)Production first inspection–To ensure the critical dimension in mass production.

(3)Sampling inspection–Check the quality before sending to the warehouse.

(4)Pre-shipment inspection–100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

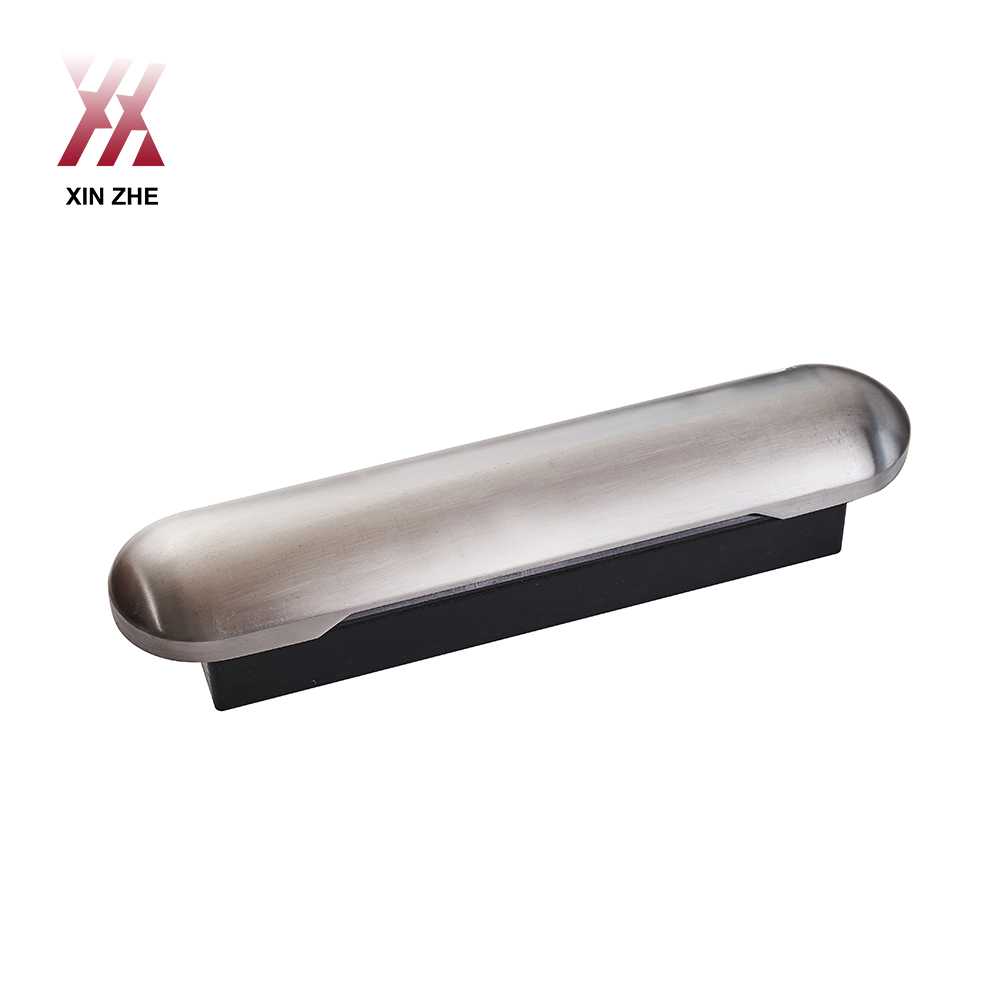

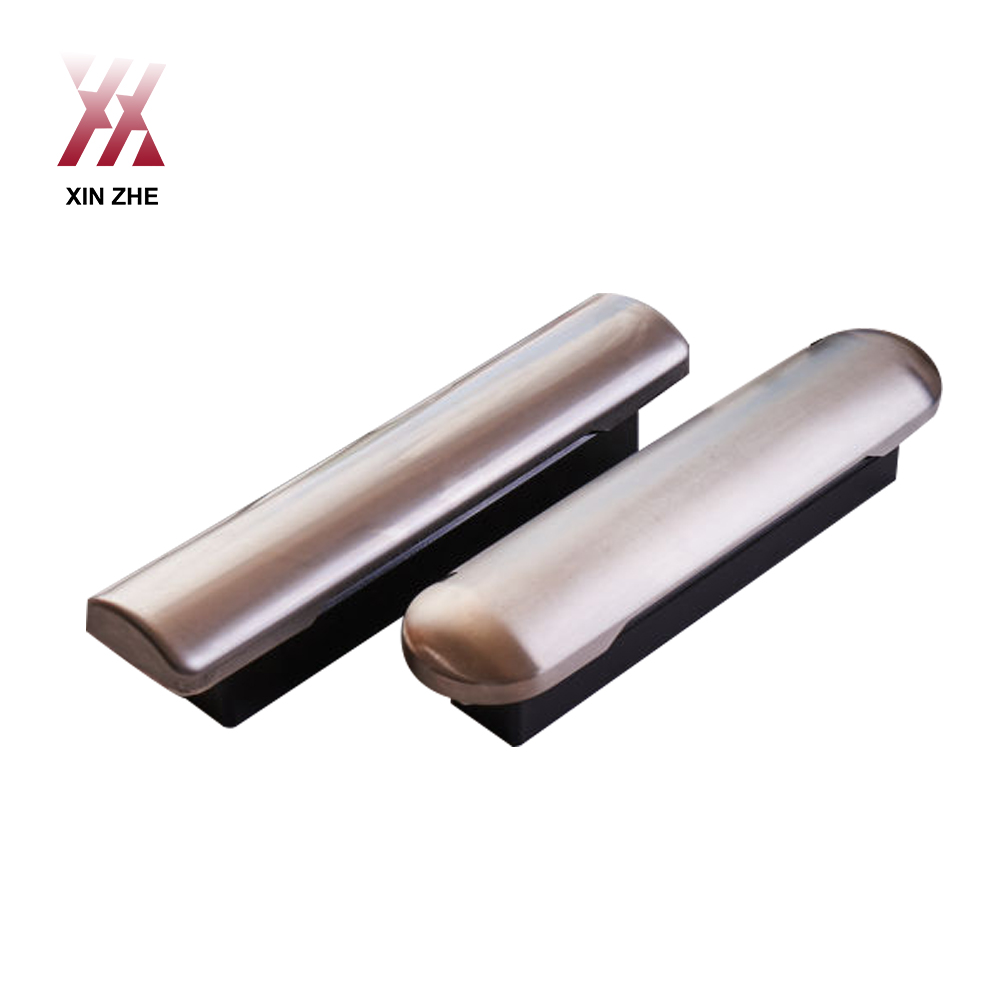

Product detail pictures:

Related Product Guide:

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of OEM High Quality Turbine Inlet Gaskets Service – Custom sheet pressed metal cutting parts metal stamping parts – Xinzhe , The product will supply to all over the world, such as: San Francisco, Comoros, Israel, Adhering to the principle of Enterprising and Truth-Seeking, Preciseness and Unity, with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective products and meticulous after-sales service. We firmly believe that: we are outstanding as we are specialized.

We have been looking for a professional and responsible supplier, and now we find it.