OEM High Quality Stamping Auto Parts Company – High Quality Metal Stamping Parts OEM Hose Clamp for auto parts – Xinzhe

OEM High Quality Stamping Auto Parts Company – High Quality Metal Stamping Parts OEM Hose Clamp for auto parts – Xinzhe Detail:

Description

Features

1. standard fastener inner diameter 11mm , 65Mn material, thickness 0.8mm, hardness 38-42 degrees , the product is used in auto parts, Easy structure,easy maked.

2.Edge is no burrfree,it is ability to prevent the tube damaged

3.By a efficiently hydrogen relief treatment,long-term use needn’t to worry fracture and other problems.

4.Accord with DIN3017 Standard.By 72 hours salt and fog test,it has a good corrosion resistance.

5.By last 36 hours elastic test,to insure a high strength mechanical properties.

6.Easy to fix.

Technology Standard

1. Chemical analysis and metallographic examination are used to analyze the content of chemical elements in the materials, determine the grade and uniformity of grain size, evaluate the grade of free cementite, banded structure and non-metallic inclusions in the material, and check the defects such as shrinkage cavity and porosity.

2. Material inspection the processing materials of stamping parts are mainly hot-rolled or cold-rolled (mainly cold-rolled) metal sheet and strip materials. The raw materials of metal stamping parts shall be provided with quality certificates to ensure that the materials meet the specified technical requirements. When there is no quality certificate or for other reasons, the hardware stamping parts manufacturer can select raw materials for re inspection according to the needs.

3. The formability test includes bending test, cupping test, determination of work hardening index n and plastic strain ratio R. in addition, the formability test method of steel sheet can be carried out according to the regulations of formability and test method of sheet steel.

4. Hardness test the hardness of metal stamping parts is tested by Rockwell hardness tester. Small, complex shape stamping parts can be used to test the plane is very small, can not be tested on the ordinary table Rockwell hardness tester.

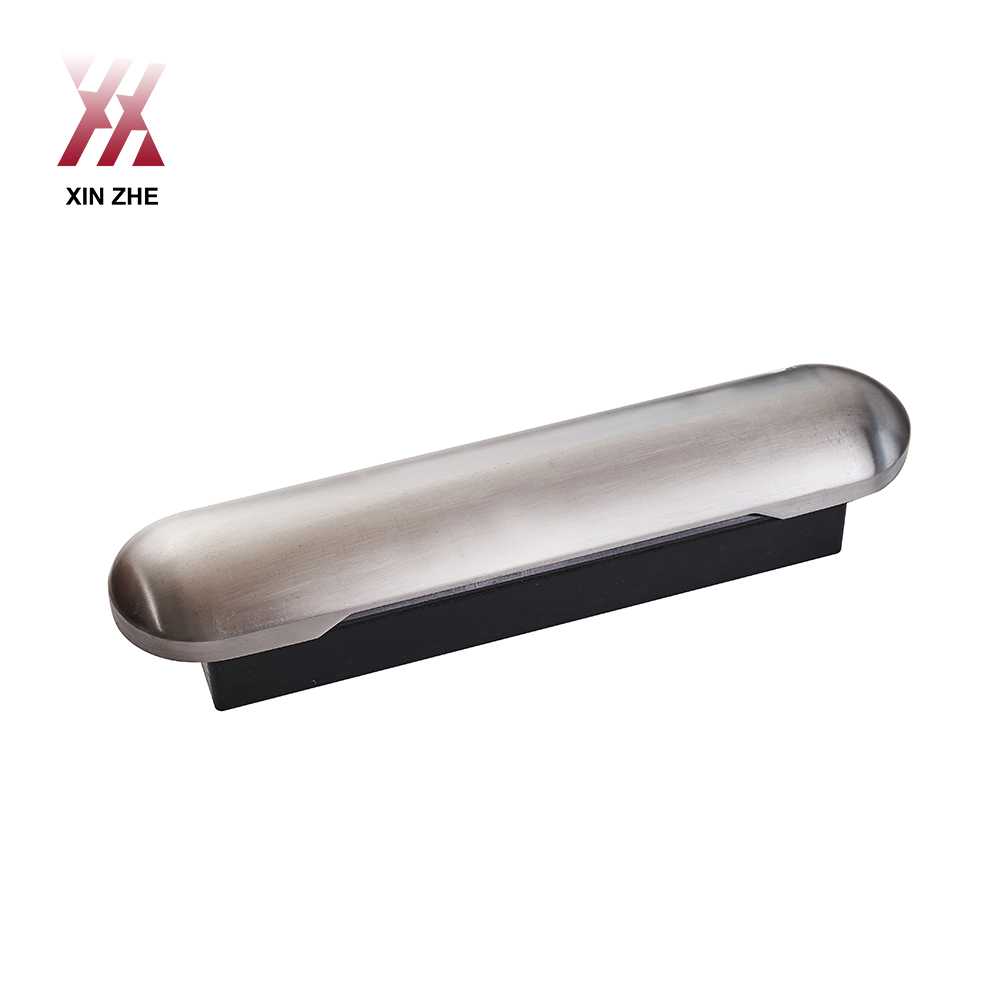

Product detail pictures:

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for OEM High Quality Stamping Auto Parts Company – High Quality Metal Stamping Parts OEM Hose Clamp for auto parts – Xinzhe , The product will supply to all over the world, such as: Iceland, Swedish, Bandung, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!