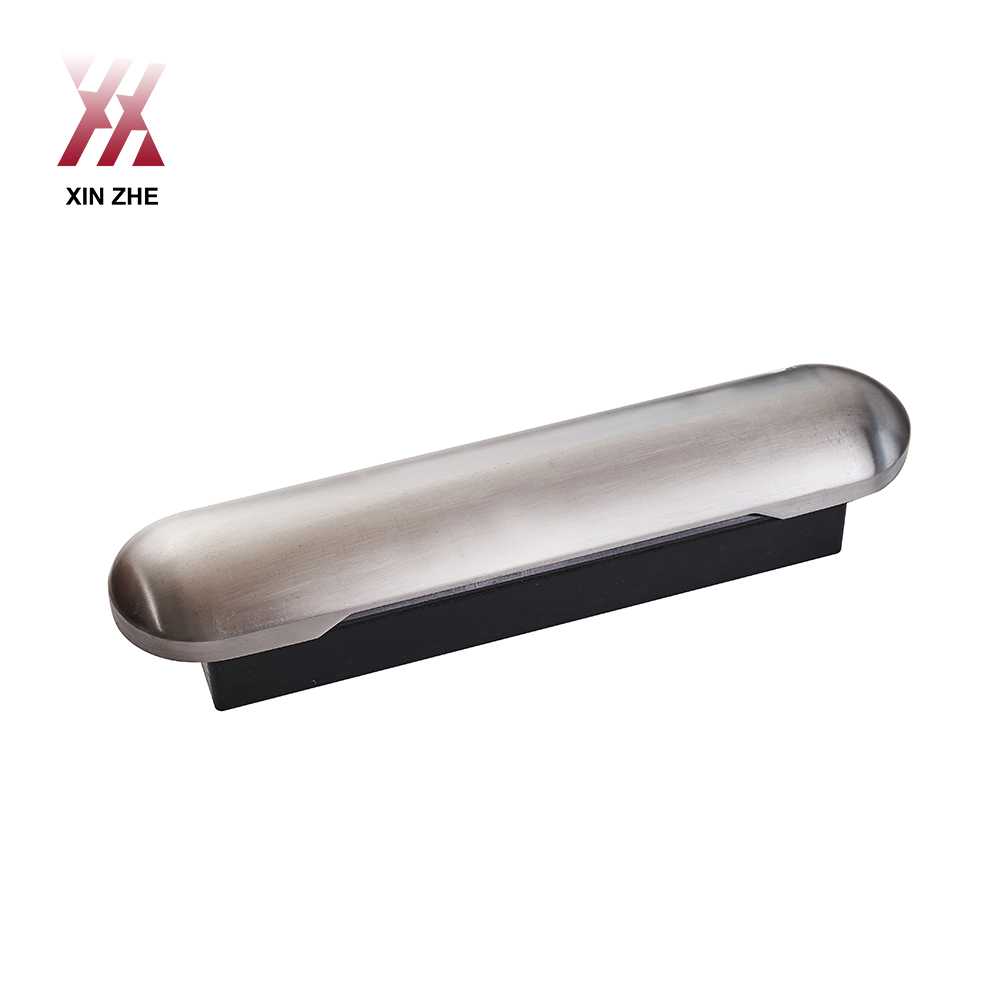

OEM High Quality Electrical Stamping Parts Bottom Plate Manufacturer – Stainless Steel Sheet Metal Forming Stamping Bending Welding Stamping Parts – Xinzhe

OEM High Quality Electrical Stamping Parts Bottom Plate Manufacturer – Stainless Steel Sheet Metal Forming Stamping Bending Welding Stamping Parts – Xinzhe Detail:

Description

Services Standards

How to Verify Quality of Metal Stamping Services

Blanking inspection standard:

1. The sharp corners, edges, and rough edges that may cause damage should be deburred.

2. The surface should have no obvious protrusions, depressions, roughness, scratches, rust and other defects.

Bending inspection standard:

1. You can see creases, but you should not feel them when you touch them.

2. The bending direction and size are consistent with the drawings.

Inspection standard of Metal Stamping processing parts:

1. Pressure riveting parts: After pressing on the parts, the thread must not be deformed. The pressure riveting parts should be flat with the board surface, there should be no protrusions or recesses, the hand feeling is smooth and smooth, and there should be no burrs.

2. Welding: The welding seam should be firm and uniform, and there will be no defects such as false welding, cracks, incomplete penetration, weld penetration, gaps, undercuts, etc.

3. Welding point requirements: the position of the welding point should be symmetrical, and the upper and lower positions should be unified. Under special circumstances, it should be implemented in accordance with the drawings. After welding, there should be no obvious welding scars, and other parts should not be damaged by welding slag or arc.

4. After welding, the outer surface of the parts should be free of slag inclusions, pores, weld bumps, bumps, depressions and other defects, and the defects on the inner surface should not be obvious and do not affect the assembly

5. The outer surface of the welded parts should be ground flat.

Why choose us?

Quality Commitment

1. Product manufacture and inspection are with quality records and inspected data.

2. We guarantee products provided qualified in consistent with national and international industry standards, ensure that all equipment are strictly in accordance with the contract tenders, ensure that all the devices out of the box 100% qualified, acceptance criteria for test for 48hours in a row without a glitch.

Price Commitment

1.Materials from premium brands home and broad make products highly advanced and reliable.

2.Under the same conditions of competition, we offer favorable price without any technical change and quality elimination.

FAQ

1Q: Are you trading company or manufacturer?

A: We are factory, so we can provide competitive price for you.

2Q: What kind of service can you provide?

A: Our company (Runze) can provide OEM sheet metal fabrication, CNC machining and manufacturing service.

3Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

Product detail pictures:

Related Product Guide:

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for OEM High Quality Electrical Stamping Parts Bottom Plate Manufacturer – Stainless Steel Sheet Metal Forming Stamping Bending Welding Stamping Parts – Xinzhe , The product will supply to all over the world, such as: Mauritius, Uruguay, Ghana, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.