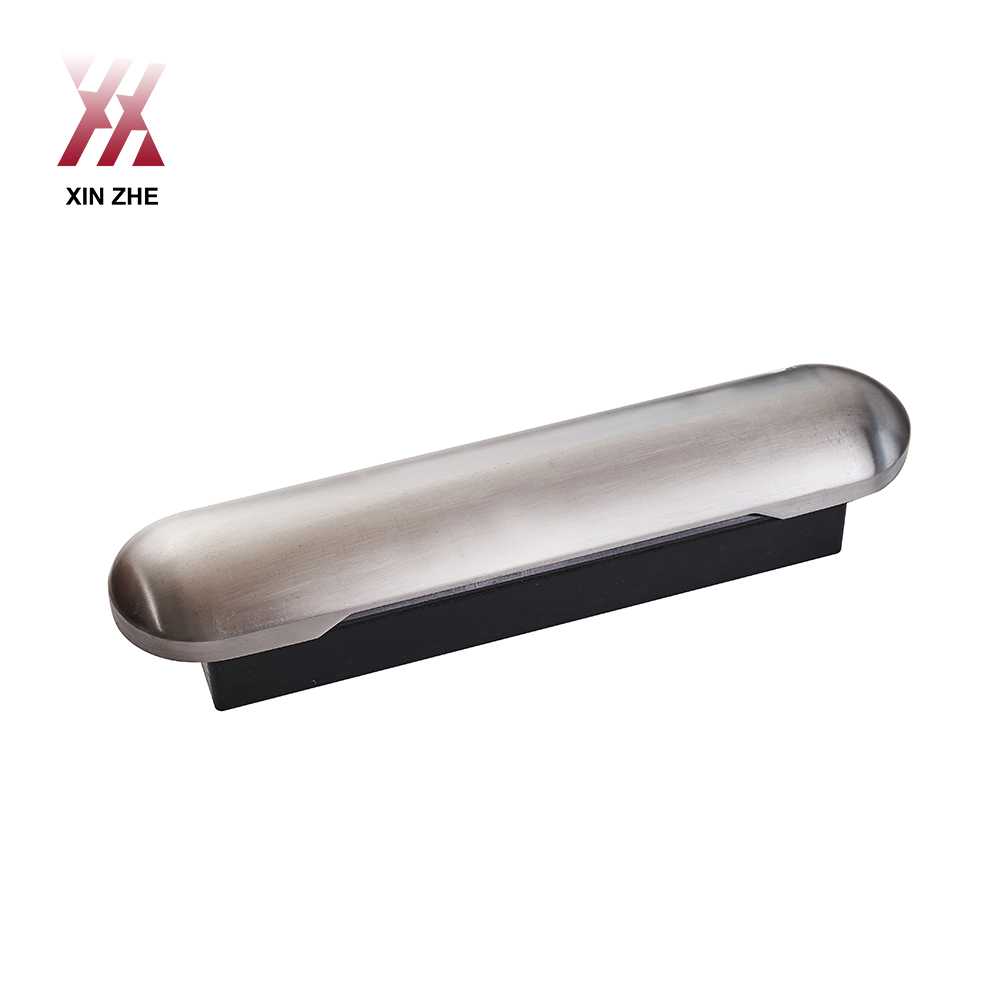

ODM Automotive Components Manufacturer – Customized Carbon Steel oil Deflector Oil Baffle Cold Stamping Parts – Xinzhe

ODM Automotive Components Manufacturer – Customized Carbon Steel oil Deflector Oil Baffle Cold Stamping Parts – Xinzhe Detail:

Description

Product Advantages

*. Good Quality Best Price competitive strength products

*. No-Standard/Standard/ OEM/ODM/ Customized service provided

*. Can meet DIN,JIS,ASTM,AISI, BS,GB standard

*. Small order available

*. Fast lead time

*. Timely after-sales services

Service

Metal Stamping processing service

The technological process of Metal Stamping processing services: cutting → bending buckle → bending forming → welding → riveting.

Pressure riveting: The process of firmly crimping fasteners such as pressure riveting nuts and pressure riveting screws on the workpiece using a punch or hydraulic press.

Riveting: The process of first countersinking the workpiece, and then using a punch or hydraulic press to firmly crimp the rivet nut on the workpiece.

Corner cutting: refers to the process of cutting off the corners of the workpiece using a die on a punch or hydraulic press.

Bending: refers to the process of forming a workpiece using a bending machine.

Forming: refers to the process of using a mold to deform a workpiece on an ordinary punch or other equipment.

Cutting material: The process of using a shearing machine to make a material into a rectangular workpiece.

Punching: The process of using ordinary punches and molds to make holes for the workpiece.

Stamping: refers to the process of stamping out characters, symbols or other imprints on the workpiece using a mold.

Reaming: The process of processing small holes on the workpiece into large holes, mainly using drills or milling cutters for operation.

FAQ

1Q: Are you trading company or manufacturer?

A: We are factory, so we can provide competitive price for you.

2Q: What kind of service can you provide?

A: Our company can provide OEM sheet metal stamping manufacturing service.

3Q: What’s kinds of information you need for a quote?

A: In order to quote for you earlier, please provide us the following information together with your inquiry.

1). Detailed drawings (STEP, CAD, SOLID Works, PROE, DXF and PDF)

2). Material requirement (SUS, SPCC, SECC, SGCC, Copper, AL, ETC.)

3). Surface treatment (powder coating, sand blasting, planting, polishing, oxidization, brushing, etc.)

4). Quantity (per order/ per month/ annual)

5). Any special demands or requirements, such as packing, labels, delivery, etc.

4Q: What shall we do if we do not have drawings?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

Product detail pictures:

Related Product Guide:

We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for ODM Automotive Components Manufacturer – Customized Carbon Steel oil Deflector Oil Baffle Cold Stamping Parts – Xinzhe , The product will supply to all over the world, such as: Costa rica, Mali, Iceland, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of innovation, harmony, team work and sharing, trails, pragmatic progress. Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.