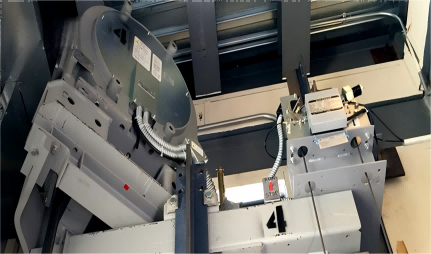

Machine room-less elevators are relative to machine room elevators. That is to say, modern production technology is used to miniaturize the equipment in the machine room while maintaining the original performance, eliminating the machine room, and moving the control cabinet, traction machine, speed limiter, etc. in the original machine room to the top or side of the elevator shaft, thereby eliminating the traditional machine room.

Image source: Mitsubishi Elevator

The guide rails and guide rail brackets of machine room-less elevators and machine room elevators are similar in function, but there may be differences in design and installation, mainly depending on the following factors:

Installation position of guide rails

Machine room elevators: Guide rails are usually installed on both sides of the elevator shaft, and the installation process is relatively conventional because the location of the machine room and the corresponding equipment layout have been considered in the shaft design.

Machine room-less elevators: The installation position of the guide rails may be adjusted to adapt to the compact shaft space. Since there is no machine room, equipment (such as motors, control cabinets, etc.) are usually installed on the top or side walls of the shaft, which may affect the layout of the guide rails.

Design of guide rail brackets and guide rail connecting plates

Elevators with machine rooms: The design of guide rail brackets and guide rail connecting plates is relatively standardized, usually following established industry specifications, suitable for most elevator shaft designs and guide rail types, and more consideration is given to the docking stability and mechanical properties of the guide rails. They are relatively convenient to install and adjust.

Machine room-less elevators: Since the shaft space is more compact, the design of guide rail brackets and guide rail connecting plates needs to be customized according to the installation location of the equipment, especially when there are more equipment at the top of the shaft. It needs to be more flexible to adapt to more complex shaft structures and different guide rail connection methods.

Structural load

Elevators with machine rooms: Since the weight and torque of the machine room equipment are borne by the machine room itself, the guide rails and brackets mainly bear the weight and operating force of the elevator car and counterweight system.

Machine room-less elevators: The weight of some equipment (such as motors) is directly installed in the shaft, so the guide rail brackets may need to bear additional loads. The design of the bracket needs to take these additional forces into account to ensure the smooth operation of the elevator.

Image source: Elevator World

Difficulty of installation

Elevator with machine room: Since the shaft and machine room usually have more space, the installation of guide rails and brackets is relatively simple, and there is more room for adjustment.

Elevator without machine room: The space in the shaft is limited, especially when there are equipment on the top or side wall of the shaft, the process of installing guide rails and brackets may be more complicated, requiring more precise installation and adjustment.

Material selection

Elevator with machine room and elevator without machine room: The guide rails, guide rail connecting plates and bracket materials of both are usually made of high-strength steel, but the guide rail brackets and guide rail connecting plates of machine room-less elevators may require higher precision and strength requirements to ensure safety and operational stability in the case of limited space.

Vibration and noise control

Elevator with machine room: The design of guide rails and brackets can usually pay more attention to vibration and noise isolation because the machine room equipment is far away from the elevator car and shaft.

Elevator without machine room: Since the equipment is installed directly in the shaft, the guide rails, guide rail connecting plates and brackets require additional design considerations to reduce the transmission of vibration and noise. Prevent the noise generated by the operation of the equipment from being transmitted to the elevator car through the guide rails.

Post time: Aug-17-2024