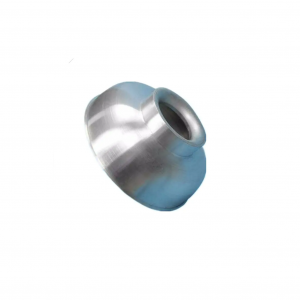

metal stamping part sheet metal punching

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Introduction to stamping

Metal stamping is a cold forming technique that creates various shapes out of sheet metal using dies and stamping equipment. A flat sheet of metal, also known as a blank, is fed into a stamping machine, which shapes the sheet into a new shape using dies and specialized tools. Companies that provide stamping services sandwich the material to be stamped between mold components and apply pressure to cut and shape it into the final form needed for the component or product. With today's sophisticated technology, mechanical equipment is necessary for every aspect of life. Examples of this include the manufacturing of automobiles, the production of medical devices, the development of aircraft equipment, etc. Then stamping parts must cooperate with these devices. This article discusses automotive stamping in brief.

The selection of automobile stamping material is contingent upon various criteria, including but not limited to part functioning, required strength and durability, weight considerations, and cost considerations. The final vehicle part's functionality and safety depend heavily on the materials selected. The following are some of the metal stamping components found in cars more frequently:

1. Body panels: these comprise the side panels, hood, trunk lid, fenders, doors, and roof.

2. Mounts and brackets, including exhaust hangers, suspension brackets, and engine brackets.

3. Elements of the chassis: strengthening plates, guide rails, and cross beams.

4. Interior components include instrument panel pieces, console panels, and seat frames.

5. Engine components, such as the cylinder head, oil pan, and valve cover.

In general, the automotive industry has found the metal stamping process to be a crucial manufacturing tool. It creates complex parts accurately, cost-effectively, and to the greatest safety and quality standards. Xinzhe is the ideal option if you're searching for a producer of hardware stamping parts.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Our service

1. Skilled research and development team – Our engineers create original designs for your products to help your business.

2. Quality Supervision Team: To guarantee that every product functions properly, it is rigorously checked before shipping.

3. Effective logistics team: until the goods is delivered to you, safety is ensured by timely tracking and tailored packaging.

4. An independent after-sales team that offers clients prompt, expert assistance around-the-clock.

5. Skilled sales team: You will receive the most professional expertise to enable you to conduct business with clients more effectively.

FAQ

Q:Are you a manufacturer or a trading company?

A: We are producers.

Q:How can I obtain a quote?

A: Please submit us your drawings (PDF, stp, igs, step...) along with the material, surface treatment, and quantity information, and we will provide you with a quote.

Q:Can I order one or two pieces for testing only?

A: Without a doubt.

Q:Can you manufacture based on the samples?

A: We are able to produce based on your samples.

Q:What's the duration of your delivery time?

A: Depending on the size of the order and the status of the product, 7 to 15 days.

Q:Do you test every item before shipping it out?

A: Before shipping, we do a 100% test.

Q:How can you establish a solid, long-term business relationship?

A:1. To guarantee our clients' benefit, we maintain high standards of quality and competitive pricing; 2. We treat every customer with the utmost friendship and business, regardless of their origins.