Manufacturing Companies for White Frame Hurricane Impact American Style Casement Window

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Manufacturing Companies for White Frame Hurricane Impact American Style Casement Window, We have been keeping chasing WIN-WIN problem with our purchasers. We warmly welcome consumers from everywhere in the planet coming in excess of for a visit and establishing long-term connection.

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Casement Windows White Frame, China UPVC Glass Window, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our goods to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

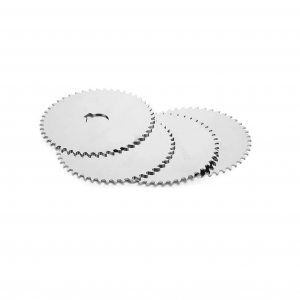

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer’s drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

The Stamping Process

Metal stamping is a manufacturing process in which coils or flat sheets of material are formed into specific shapes. Stamping encompasses multiple forming techniques such as blanking, punching, embossing, and progressive die stamping, to mention just a few. Parts use either a combination of these techniques or independently, depending on the piece’s complexity. In the process, blank coils or sheets get fed into a stamping press which uses tools and dies to form features and surfaces in the metal. Metal stamping is an excellent way to mass-produce various complex parts, from car door panels and gears to small electrical components used in phones and computers. Stamping processes are highly-adopted in automotive, industrial, lighting, medical, and other industries.

Metal Stamping FAQs

Q: What is metal stamping?

A: Metal stamping is a broad category of manufacturing services used to process metal strips or sheets into functional parts.

Q: Which industries use metal stampings?

A: Metal stampings are widely used in almost every industry, including automotive, manufacturing, construction, aerospace, electronics, medical, and more.

Q: What machine produces metal stamping parts?

A: There are many types of machines that can produce metal stampings. The most common one is the progressive die in a stamping press, other machines include multi-slide and four-slide.

Q:What are the processes involved in metal stamping?

A: Some examples of precision stamping manufacturing processes include bending, blanking, stamping, embossing, flanging, high speed, progressive die, punching, and single-stage stamping.

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Manufacturing Companies for White Frame Hurricane Impact American Style Casement Window, We have been keeping chasing WIN-WIN problem with our purchasers. We warmly welcome consumers from everywhere in the planet coming in excess of for a visit and establishing long-term connection.

Manufacturing Companies for China UPVC Glass Window and Casement Windows White Frame, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our goods to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.