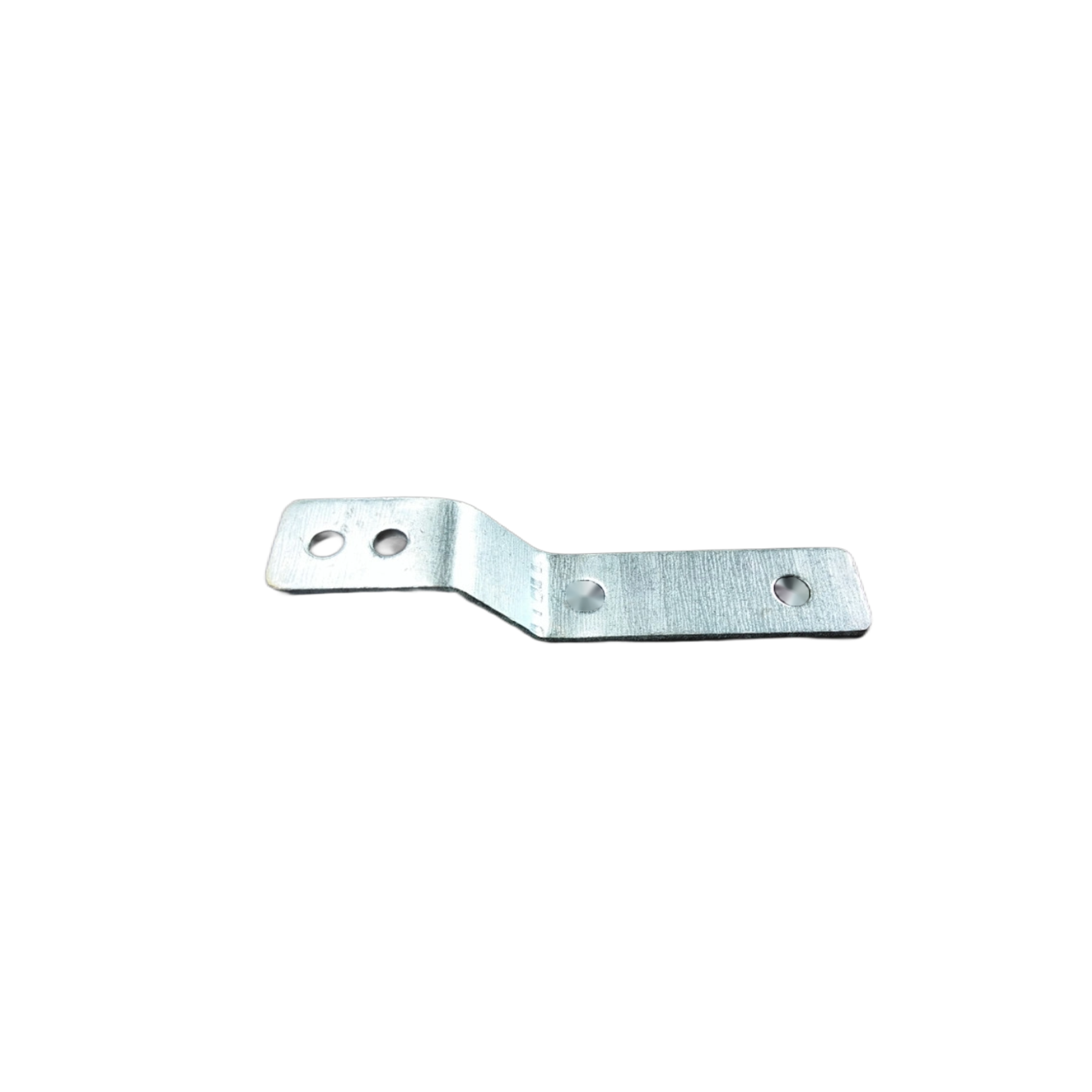

Low MOQ for Sheet Metal Stamping Bending Bracket

We pursue the administration tenet of “Quality is superior, Services is supreme, Standing is first”, and will sincerely create and share success with all customers for Low MOQ for Sheet Metal Stamping Bending Bracket, Created goods with brand benefit. We attend seriously to produce and behave with integrity, and with the favor of clients at home and overseas from the xxx industry.

We pursue the administration tenet of “Quality is superior, Services is supreme, Standing is first”, and will sincerely create and share success with all customers for China Bracket Parts and Bending, Now we have our own registered brand and our company is developing rapidly owing to high quality merchandise, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer’s drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Company Profile

As a Chinese supplier of stamped sheet metal, Ningbo Xinzhe Metal Products Co., Ltd. specializes in the manufacturing of various parts for automobiles, agricultural machinery, engineering, construction, hardware, environmentally friendly, ship, aviation, and toys, as well as hardware tools and pipe fittings.

It is to everyone’s advantage that we can enhance our clients’ market share by actively communicating with them and by getting a deeper understanding of their target market. Our commitment to provide top-notch service and premium parts is aimed at earning the trust of our clients. In order to promote cooperation, cultivate enduring ties with current clients and look for new ones in non-partner nations.

What are the commonly used metal materials for elevators?

Stainless steel

Stainless steel is one of the most common metal materials in elevators and is mainly used in elevator door covers, door edges, ceilings and wall panels. Stainless steel has the advantages of high strength, corrosion resistance, easy cleaning, and elegant appearance, and can meet the use requirements of elevators under external environmental conditions.

carbon steel

Carbon steel is mainly used for elevator structural parts, such as guide rails, light poles, support seats and door seats. Compared with stainless steel, carbon steel has higher strength and better wear resistance, and performs better in the high-intensity working environment of elevators.

Aluminum alloy

Aluminum alloy is one of the emerging materials in elevators in recent years, mainly used in elevator ceilings and wall panels. Aluminum alloy has the characteristics of light weight, high strength, strong plasticity and easy processing, which can effectively improve the overall quality of the elevator while presenting a unique modern and beautiful appearance.

brass

The application scope of brass materials is relatively small, and it is mainly used for local decoration such as elevator handrails, footings and trim strips. Brass has a golden color, high gloss, and soft texture, which can add to the overall atmosphere of the elevator.

In short, there are a wide variety of metal materials used in elevators, and each material has its own unique performance characteristics and scope of application. With the development of technology and technology, the types and performance characteristics of materials used in elevators in the future will become more diverse.

We pursue the administration tenet of “Quality is superior, Services is supreme, Standing is first”, and will sincerely create and share success with all customers for Low MOQ for Sheet Metal Stamping Bending Bracket, Created goods with brand benefit. We attend seriously to produce and behave with integrity, and with the favor of clients at home and overseas from the xxx industry.

Low MOQ for China Bracket Parts and Bending, Now we have our own registered brand and our company is developing rapidly owing to high quality merchandise, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.