Hot Sale for ODM Factory manufacture Plastic Injection Car Parts Metal Parts Stamping Mould

“Quality 1st, Honesty as base, Sincere company and mutual profit” is our idea, in an effort to create consistently and pursue the excellence for Hot Sale for ODM Factory manufacture Plastic Injection Car Parts Metal Parts Stamping Mould, To acquire a consistent, profitable, and constant development by getting a aggressive advantage, and by continuously increasing the value added to our shareholders and our employee.

“Quality 1st, Honesty as base, Sincere company and mutual profit” is our idea, in an effort to create consistently and pursue the excellence for China Die and Mould, Now we are sincerely consider to grant brand agent in different areas and our agents’ maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We have been ready to share win-win corporation.

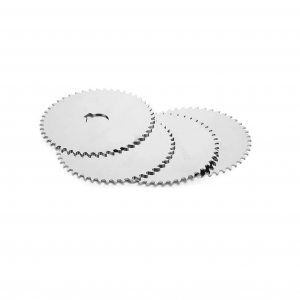

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer’s drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Quality system

All of our facilities are ISO 9001 certified. In addition, Xinzhe has extensive experience in quality control systems and processes across many industries and specific applications.

Production Parts Approval Process

Control Plan

Failure Mode and Effects Analysis (FMEA)

Measurement Systems Analysis (MSA)

initial process study

Statistical Process Control (SPC)

Our quality laboratory also builds calibration systems ranging from CMMs and optical comparators to hardness testing. Contact us to learn more.

Quality management

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Types of stamping

We offer single and multistage, progressive die, deep draw, fourslide, and other stamping methods to ensure the most effective method for manufacturing your products. Xinzhe’s experts can match your project with the appropriate stamping by reviewing your uploaded 3D model and technical drawings.

- Progressive Die Stamping uses multiple dies and steps to create deeper parts than would typically be achievable through single dies. It also enables multiple geometries per part as they go through various dies. This technique is best suited to high volume and large parts such as those in the automotive industry. Transfer die stamping is a similar process, except progressive die stamping involves a workpiece attached to a metal strip pulled through the entire process. Transfer die stamping removes the workpiece and moves it along a conveyor.

- Fourslide Stamping shapes parts from four axes instead of from one direction. This method is used to manufacture small intricate parts including electronics components such as phone battery connectors. Offering more design flexibility, lower production costs, and faster manufacturing times, fourslide stamping is popular in aerospace, medical, automotive, and electronics industries.

- Blanking cuts pieces out from the sheet as an initial step before forming. Fineblanking, a variation of blanking, makes precise cuts with smooth edges and a flat surface.

- Coining is another type of blanking that creates small round workpieces. Since it involves significant force to form a small piece, it hardens the metal and removes burrs and rough edges.

- Bending happens on a single axis and is often used to create profiles in U, V, or L shapes. This technique is accomplished by clamping one side and bending the other over a die or pressing the metal into or against a die. Flanging is bending for tabs or parts of a workpiece instead of the whole part.

FAQ

Q: Are you a trading company or manufacturer?

A: We are manufacturer.

Q: How to get the quote?

A: Please send your drawings (PDF, stp, igs, step…) to us by email , and tell us the material, surface treatment and quantities, then we will make a quotation to you.

Q: Can I order just 1 or 2 pcs for testing?

A: Yes, of course.

Q. Can you produce according to the samples?

A: Yes, we can produce by your samples.

Q: How long is your delivery time?

A: 7~ 15 days, depends on the order quantities and product process.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

“Quality 1st, Honesty as base, Sincere company and mutual profit” is our idea, in an effort to create consistently and pursue the excellence for Hot Sale for ODM Factory manufacture Plastic Injection Car Parts Metal Parts Stamping Mould, To acquire a consistent, profitable, and constant development by getting a aggressive advantage, and by continuously increasing the value added to our shareholders and our employee.

Hot Sale for China Die and Mould, Now we are sincerely consider to grant brand agent in different areas and our agents’ maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We have been ready to share win-win corporation.