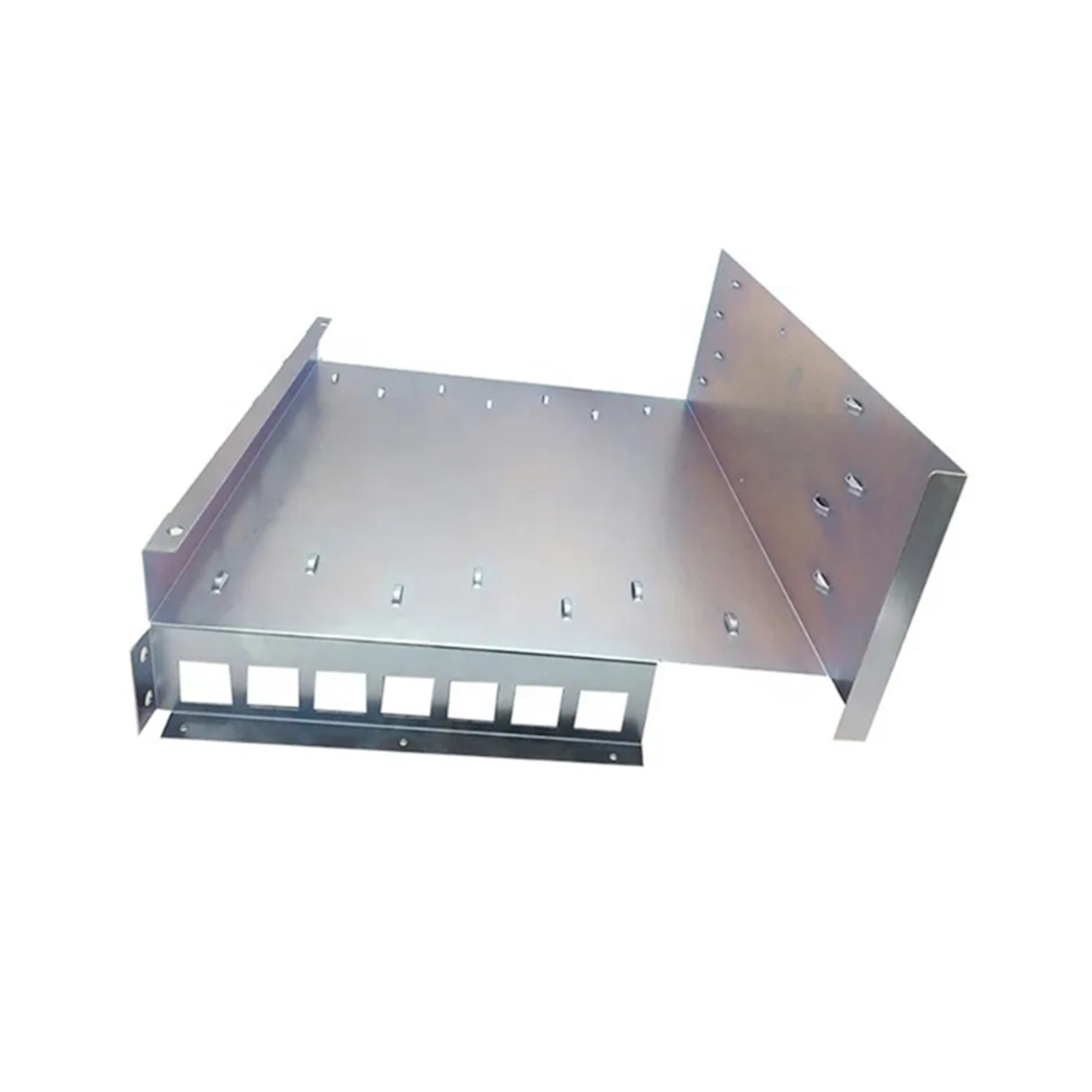

Wholesale Galvanized Bending Parts from Trusted Manufacturers

When sourcing galvanized bending parts for your business, quality and reliability are non-negotiable. As a supplier specializing in wholesale products, I focus on providing durable and precision-engineered parts that meet rigorous industry standards. Our galvanized bending parts are crafted to withstand harsh environments, ensuring longevity and excellent performance in various applications. I work closely with manufacturers who share a commitment to excellence, offering products that enhance your operational efficiency while reducing maintenance costs. Whether you’re looking to stock up for projects or needing custom solutions, our inventory is designed to meet your specific requirements. By choosing our galvanized bending parts, you’re not just purchasing a product; you’re investing in the future of your business. Let’s connect and discuss how we can support your needs in this competitive market, ensuring you get the best value for your investments.

Galvanized bending parts Market Leader Where Innovation Meets 2025

In an ever-evolving global market, the demand for galvanized bending parts continues to soar, driven by the need for durable and resilient components across various industries. As we approach 2025, innovation stands at the forefront of this sector, paving the way for advanced solutions that meet the unique requirements of clients around the world. Manufacturers are now focusing on cutting-edge technologies and innovative materials that enhance product longevity and performance, ensuring that businesses receive components that can withstand harsh conditions while maintaining structural integrity. Sustainability is another crucial consideration influencing the galvanized bending parts market. Companies are increasingly adopting eco-friendly practices in their production processes, aiming to minimize environmental impact while delivering top-quality products. This shift not only addresses growing consumer demand for sustainable solutions but also reflects a commitment to corporate responsibility. Together with advancements in automation and precision manufacturing, these trends position manufacturers to offer customized solutions that cater to the specific needs of global buyers. As we move towards 2025, collaboration with experienced manufacturers can help businesses in various sectors optimize their supply chains and improve operational efficiency. By tapping into a network of innovation-focused suppliers, global purchasers can ensure they remain competitive in an increasingly challenging market landscape. Embrace the future of galvanized bending parts—it's not just about meeting today’s standards but about setting the benchmarks for tomorrow’s innovations.

Galvanized Bending Parts Market Leader Where Innovation Meets 2025

| Dimension | Application | Material Type | Technology Used | Market Share (%) | Expected Growth (%) |

|---|---|---|---|---|---|

| 200 x 100 mm | Automobile Manufacturing | Galvanized Steel | CNC Bending | 25 | 7 |

| 300 x 150 mm | Construction | Zinc Coated Steel | Hydraulic Bending | 30 | 5 |

| 400 x 200 mm | Aerospace | Mild Steel | Laser Bending | 20 | 10 |

| 250 x 125 mm | Railway | Alloy Steel | Electric Bending | 15 | 8 |

| 150 x 75 mm | Furniture | Stainless Steel | Manual Bending | 10 | 6 |

Related Products