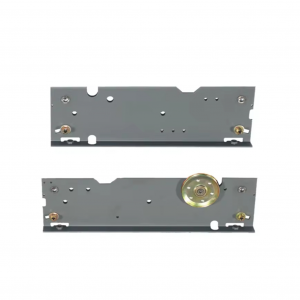

Elevator installation accessories-carbon steel side bending bracket

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Elevator accessories, engineering machinery accessories, construction engineering accessories, auto accessories, environmental protection machinery accessories, ship accessories, aviation accessories, pipe fittings, hardware tool accessories, toy accessories, electronic accessories, etc. | |||||||||||

Company Profile

We are a metal products firm with a focus on services related to sheet metal processing. With many years of experience in the field, we are dedicated to offering the construction and elevator manufacturing industries high-quality, precisely engineered sheet metal processing products and solutions. With its cutting-edge machinery, fine craftsmanship, and first-rate services, the company has successfully attained ISO9001 quality management system certification and is equipped to handle the processing requirements of a wide range of elevator parts.

The main products are steel structure connectors for construction projects, angle brackets, fixed brackets, connecting brackets, column brackets, car brackets, counterweight brackets, machine room equipment brackets, door system brackets, buffer brackets, guide rail connecting plates, bolts, nuts, screws, studs, expansion bolts, gaskets, rivets, pins, and other accessories.

Advanced inspection tools, such as three-coordinate measurement devices, are used in quality inspection to guarantee the quality of the product.

We not only provide professional sheet metal processing accessories for global mechanical equipment, automobile, and construction engineering fields. In addition, we also provide first-class supplies for elevator manufacturers such as Otis, Fujita, Kangli, Dover, Hitachi, Toshiba, Schindler, Kone, and TK.

Our goal is to consistently provide customers with high-quality spare parts and services to meet your needs, strive to increase our market share and establish a lasting cooperative relationship with you.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Advantages of metal stamping

Is stamping suitable for mass production?

Stamping is very suitable for the production of large quantities and complex parts.

It has the following advantages:

High efficiency

Mass production can be achieved with one mold forming, which is suitable for large-scale manufacturing.

High precision

The dimensions can be precisely controlled to ensure the consistency and accuracy of each product, which is particularly suitable for industries with high requirements for part precision.

Low cost

Automated production, and fast production speed, can reduce labor costs, high material utilization rate, and reduce waste.

Strong diversity

Parts of various complex shapes can be made, including bending, punching, trimming, etc., to meet diverse design needs.

High material utilization rate

Less material waste during stamping, maximum utilization of metal materials, and reduced costs.

FAQ

1. Q: What is the payment method?

A: We accept TT (bank transfer), L/C.

(1. If the total amount is less than 3000 USD, 100% prepaid.)

(2. If the total amount is more than 3000 USD, 30% prepaid, the rest paid by copy.)

2.Q: Where is your factory?

A: Our factory is located in Ningbo, Zhejiang.

3. Q: Do you provide free samples?

A: Usually we do not provide free samples. There is a sample fee, which can be refunded after placing an order.

4. Q: How do you usually ship?

A: There are common modes of transportation such as air, sea, and land.

5. Q: I don’t have drawings or pictures of customized products, can you design them?

A: Yes, we can make the most suitable design according to your samples.