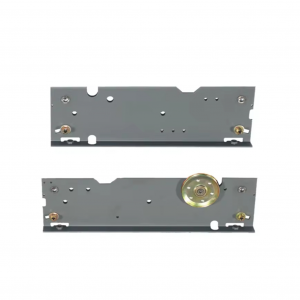

Elevator hall door car door slider Elevator door guide shoe

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Introduction

The metal materials used for elevator guide boots are mainly determined based on their performance requirements and working environment. In elevator systems, guide shoes need to have sufficient strength and wear resistance to withstand the pressure and friction generated when the elevator is running.

Common metals that can be used for elevator guide boots include steel, iron, alloy steel, etc. These metal materials have excellent mechanical properties, such as high strength, good wear resistance and corrosion resistance, and can meet the needs of elevator guide boots during work.

Specifically, alloy steel may be an ideal choice because it combines the benefits of multiple metals, offering greater strength and wear resistance while potentially offering some resistance to corrosion. This material ensures that the elevator guide shoes maintain stable performance over long periods of use and reduces failures caused by wear and aging.

However, it should be noted that although metal guide shoes have excellent performance, they may also have some disadvantages, such as heavier weight and louder noise. Therefore, when selecting metal materials for elevator guide boots, it is necessary to comprehensively consider factors such as performance, cost, weight, noise, etc., and make a reasonable choice based on the specific elevator type and operating requirements.

In addition, with the development of materials science and technology, more new metal or alloy materials may appear for the manufacture of elevator guide boots to improve their performance and lifespan. Therefore, it is recommended to consult with a professional elevator manufacturer or supplier to obtain the latest material selection and technical information when selecting elevator guide boots.

Xinzhe Metal Stamping Parts is a leading stamped metal parts manufacturer, producing custom parts in a variety of base materials. We offer a wide range of precision metal stamping capabilities, including: blanking, bending, stamping, forming, punching and more.

We have precision metal stamping capabilities to produce complex, high-quality parts from a variety of materials. We use state-of-the-art equipment and technology to ensure our parts meet the highest quality standards.

FAQ

1. Q: How will I make my payment?

A: We take L/C and TT (bank transfer).

(1. )100% in advance for amounts under $3000 USD.

(2. )30% in advance for amounts over US$3,000; the remaining money is due upon receipt of a copy of the document.

2.Q: What location is your factory?

A: We have our factory in Ningbo, Zhejiang.

3. Question: Do you offer free samples?

A: Typically, we don't give away free samples. After placing your order, you can get a refund for the sample cost.

4.Q: Which channel do you often ship through?

A:Due of their modest weight and size, air freight, sea freight, and express shipping are the most popular methods of product shipment.

5.Q: Could you design the picture or drawing I don't have for the bespoke products?

A: We are able to create the most appropriate design based on your application.