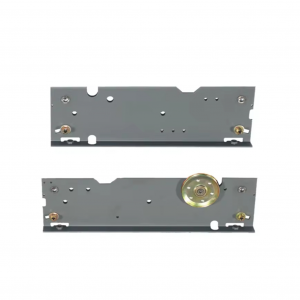

Elevator fishplates for machined, cold drawn and hollow rails

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Elevator accessories, engineering machinery accessories, construction engineering accessories, auto accessories, environmental protection machinery accessories, ship accessories, aviation accessories, pipe fittings, hardware tool accessories, toy accessories, electronic accessories, etc. | |||||||||||

Advantages

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 25-40 days.

4. Strict quality management and process control (ISO 9001 certified manufacturer and factory).

5. Factory direct supply, more competitive price.

6. Professional, our factory serves the sheet metal processing industry and uses laser cutting technology for more than 10 years.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Carbon steel products

Elevator guide rail connection plates are usually made of carbon steel. Carbon steel is widely used in the production of elevator guide rail connection plates due to its high strength, good machinability and low cost. Carbon steel has the following advantages, making it a common material for elevator guide rail connection plates:

High strength: Carbon steel can provide sufficient strength to withstand the forces generated during the operation of the elevator guide rails, ensuring the stability and safety of the connection.

Good weldability: Carbon steel materials are easy to weld, which facilitates the processing and assembly of connection plates during the manufacturing process.

Durability: Carbon steel has good wear resistance and fatigue resistance, can withstand friction and stress in long-term use, and prolong service life.

Cost-effectiveness: Compared with other alloy steels or stainless steels, carbon steel has a lower cost, making it an economical choice for manufacturing elevator guide rail connection plates.

However, in some special cases (such as those requiring higher corrosion resistance), galvanized or other surface-treated carbon steel may be used, or alloy steel, stainless steel and other materials may be selected to meet specific use environment requirements.

Xinzhe Metal Products provides you with high-quality sheet metal processing products for the construction industry: fixing brackets, connecting brackets, elevator guide rails, guide rail connecting plates, angle brackets, U-shaped brackets, L-shaped brackets, U-shaped gaskets and various standard models of fasteners.

FAQ

Q1: What is the minimum order quantity?

A1: Generally there is no minimum order quantity, it is up to you to decide. The quantity determines the pricing。

Q2: How long is your delivery time?

A2: It takes about two days for stock products, about five days for custom design samples, and about 35 days for mass production after sample approval and deposit。

Q3: Can it be customized?

A3: Customization is our strong point.

Q4: How do you deliver the goods?

A4:1) We can use DHL, FEDEX, TNT, UPS, EMS or the agent of your choice for express delivery!

2) By sea

3) By air

Q5: What guarantee do you provide?

A5: We pack each item in a sturdy wooden box and check it many times. And will track each item until it reaches your company。