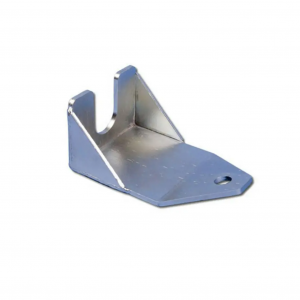

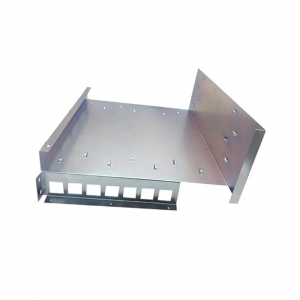

Electrophoretic paint bracket sheet metal stamping and bending parts

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Process flow

The main steps of the electrophoretic paint process:

1. Surface treatment: Treat the surface of metal products, including removing impurities such as oil stains and rust, to ensure the adhesion of the paint film and the coating effect after painting.

2. Cathodic electrophoretic primer: Metal products are immersed in pre-mixed primer and used as a cathode for electrophoretic coating. In the electrophoretic coating tank, the primer particles are negatively charged and combine with the anode on the metal product to form a uniform coating, so that the surface of the metal product can achieve a certain anti-corrosion effect.

3. Drying and curing: After coating with cathodic electrophoresis primer, metal products need to be dried and cured. The curing temperature and time depend on the material and thickness of the primer. Through high-temperature curing, the primer can form a strong protective film and improve the corrosion resistance of metal products.

4. Intermediate coating: After primer treatment, metal products need to be coated with one or more intermediate coatings to enhance the adhesion and weather resistance of the paint film.

5. Top coat electrophoresis: After the intermediate coating is completed, the metal products are top coat electrophoresis coated. After topcoat electrophoretic coating, a uniform and smooth paint film will be formed on the surface of the metal product.

6. Terminal drying and curing: After the topcoat is electrophoresed, the metal products undergo terminal drying and curing.

The completion of the electrophoretic paint process not only improves the anti-corrosion performance and appearance quality of metal products, but also reduces the use of organic solvents and reduces environmental pollution. The application of electrophoretic paint plays an important role in the field of metal coating, especially in the automotive industry.

The specific electrophoretic paint process will vary depending on application occasions, product requirements, equipment conditions and other factors. In actual operation, it needs to be adjusted and optimized according to specific conditions to achieve the best painting effect.

FAQ

1.Q: What is the payment method?

A: We accept TT (Bank Transfer), L/C.

(1. For total amount under US$3000, 100% in advance.)

(2. For total amount above US$3000, 30% in advance, the rest against the copy document.)

2.Q:Where is your factory located?

A:Our factorty is located in Ningbo,Zhejiang.

3.Q:Do you provide free samples?

A:Usually we do not provide free samples. There is a sample cost which can be refund after you place order.

4.Q:What do you usually shipped through?

A:Air freight, Sea freight, express are the most way of shipment due to small weight and size for precise products.

5.Q:I don’t have drawing or picture available for custom products, could you design it?

A:Yes, we can make the best suitable design in accordance with your application.