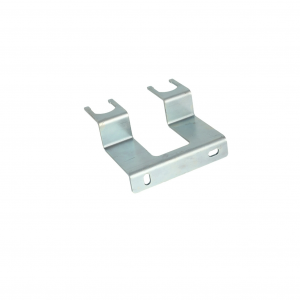

Customized sheet metal forming stamping parts for auto parts

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Material selection

When selecting materials, first select metal materials with different mechanical properties based on the type of automotive stamping and usage characteristics, so as to ensure product quality and save materials.

Generally, the following principles should be followed when selecting automotive stamping parts materials:

1. The selected materials should first meet the performance requirements of automobile parts;

2. The selected materials must have good process performance;

3. The selected materials must be economical.

A large number of cold stamping processes are used in the production of automotive stamping parts, which is suitable for the multi-variety and mass production needs of the automotive stamping parts industry. In medium and heavy-duty vehicles, most covering parts such as body outer panels, and some load-bearing and supporting parts such as frames, compartments and other auto parts are automotive stamping parts. The steel materials used for cold stamping are mainly steel plates and steel strips, accounting for 72.6% of the steel consumption of the entire vehicle. The relationship between cold stamping materials and the production of automotive stamping parts is very close: the quality of the material not only determines the performance of the product, but also directly affects the performance of the product. The process design of automobile stamping parts technology affects the quality, cost, service life and production organization of the product. Therefore, the reasonable selection of materials is an important and complex task.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Material selection

Anodized materials mainly include aluminum and its alloys, magnesium and its alloys, titanium and its alloys, stainless steel, zinc and its alloys, cemented carbide, glass, ceramics and plastics, etc.

Anodizing is an electrochemical surface treatment technology that can form an oxide film on the surface of these materials, which can enhance the corrosion resistance, hardness, wear resistance, electrical insulation and other properties of the materials. For example: after aluminum alloy is anodized, its surface can form a hard, smooth, and non-shedding oxide film, which is widely used in aviation, automobiles, electronics, etc.

When choosing bespoke metal stamping components, why go with Xinzhe?

Xinzhe is a professional metal stamping expert that you visit. Serving clients worldwide, we have specialized in metal stamping for almost a decade. Our mold specialists and highly qualified design engineers are committed and professional.

What's the key to our accomplishments? Two words can sum up the response: quality assurance and specs. For us, each project is distinct. It is driven by your vision, and it is our duty to bring that vision to pass. We attempt to comprehend every aspect of your project in order to achieve this.

We'll get to work on producing your idea as soon as we know it. Along the way, there are several checkpoints. This enables us to guarantee that the finished product fully satisfies your needs.

Our group currently focuses on providing custom metal stamping services in the following fields:

Stamping in stages for both small and big quantities

Secondary stamping in small batches

tapping within the mold

Taping for secondary or assembly

Machining and shaping