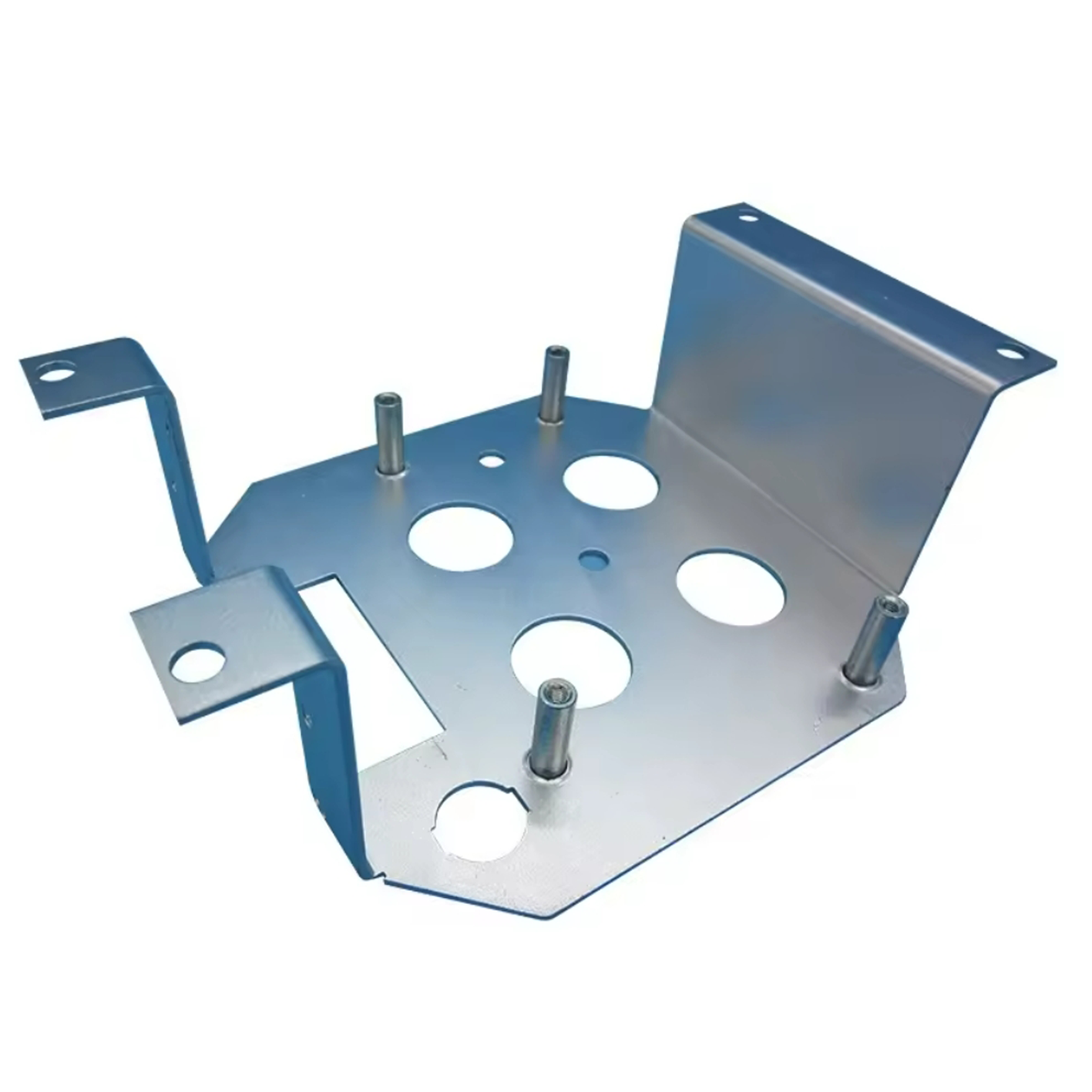

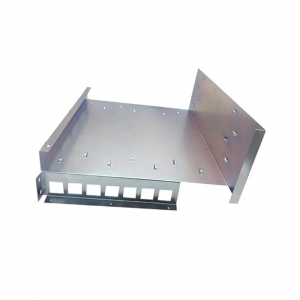

Customized precision sheet metal processing galvanized machinery accessories

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Quality Warranty

1. All product manufacturing and inspection have quality records and inspection data.

2. All prepared parts undergo strict testing before being exported to our customers.

3. If any of these parts are damaged under normal working conditions, we promise to replace them one by one for free.

That's why we're confident any part we offer will do the job and come with a lifetime warranty against defects.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Company Profile

Xinzhe Metal Stamping Parts uses our lifetime tooling, which is exclusive, to create 50 to 500,000 metal stamping parts. From the most straightforward to the most intricate designs, our in-house mold business is well known for producing high-quality molds.

Because Xinzhe Metal Stamping's knowledgeable staff is familiar with the properties of every material used in metal stamping parts, we can help clients select the most cost-effective materials for their projects involving metal stamping. Our metal stamping service shop is sufficiently big to offer comprehensive services, yet manageable enough to collaborate with you on a daily basis. One of our objectives is to reply to inquiries for quotes in a day or less.

Apart from primary certification procedures including heat treatment, penetrant testing, painting, galvanizing, and electroplating, we will also offer secondary certification processes like these. On-time, high-quality part delivery is Xinzhe Metal Stamping Co., Ltd.'s greatest pride. Put simply, selecting Xinzhe metal stamping parts gives you peace of mind.

Galvanized parts field

There are numerous uses for galvanized materials, such as:

1. Construction: A wide range of applications, including water, air, and electrical wire pipes as well as steel beams, use galvanized steel pipes.

2. The production of automobiles: Due to their excellent strength and resistance to corrosion, galvanized steel sheets are utilized in the production of car bodywork and parts.

3. Building materials: Walls, fences, roofing, and other structures are constructed using galvanized steel wire mesh and sheets.

4. Food processing: Galvanized steel cookware and utensils are frequently used in the food processing sector since they are hygienic and easy to clean.

5. Electrical equipment: To increase its durability and corrosion resistance, electrical equipment uses galvanized ground wires, sleeves for protecting cables, and other materials.

6. Metallurgical industry: To increase the equipment's resistance to corrosion and high temperatures, galvanized steel is used in the construction of furnaces, furnace doors, pipelines, and other metallurgical machinery.