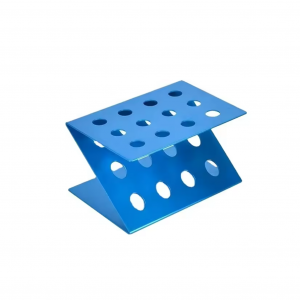

Customized hardware elevator bracket-guide rail bracket

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Process flow

The surface treatment process during the manufacturing process of elevator guide rail brackets includes the following key steps:

1. Cleaning: First, clean the elevator guide rails to remove impurities and oil on the surface to prepare for subsequent surface treatment.

2. Laser cladding: Use a specific ratio of cemented carbide powder (including titanium carbide powder, tungsten carbide powder, molybdenum powder, nickel powder and cobalt powder) for laser cladding to enhance the hardness and wear resistance of the elevator guide rail surface .

3. Nitriding treatment: After laser cladding, the elevator guide rails are surface nitrided to improve their hardness and wear resistance. This step is completed in a hot isostatic pressing furnace, using nitrogen as the working gas, and the working pressure It is 80MPa, and the nitriding time is about 80-120 minutes.

4. Heat treatment: The nitrided elevator guide rail is heat treated at a temperature of 440-480 degrees Celsius to further optimize its surface properties, and the heat preservation time is 1-2 hours.

In addition to the main steps mentioned above, the surface treatment of elevator guide rail brackets may also include the following auxiliary measures:

Coating - Plating: Improve the durability and corrosion resistance of the guide rail by adding wear-resistant coatings, anti-corrosion coatings or other special coatings.

Anodizing: Suitable for aluminum alloy guide rails. Anodizing improves surface hardness and corrosion resistance.

Polishing: Improves the smoothness of the guide rail surface, reduces friction and wear, and is often used in high-precision and low-friction applications.

FAQ

Q1: What should we do in the event that we lack drawings?

A1: Send your sample to our factory so we can duplicate it or offer you better options. In order for us to create a CAD or 3D file for you, please provide us images or drafts with the dimensions (thickness, length, height, and width).

Q2: How do you distinguish yourself from others?

A2: 1) Our Outstanding Assistance If you can provide detailed details within business hours, we can provide the quotation in 48 hours.

2) Our prompt production schedule We guarantee to produce within 3–4 weeks for regular orders. In accordance with the official contract, we, as the factory, can guarantee the delivery time.

Q3: Is it feasible to learn about the success of my items without physically visiting your business?

A3: We'll give you a thorough manufacturing schedule and send you weekly reports that include pictures or videos of the machining process.

Q4: Can I request a sample or trial order for a few items only?

A4: Sample costs will be incurred because the product is tailored and must be made; however, if the sample is not more expensive than the bulk order, the sample costs will be reimbursed.