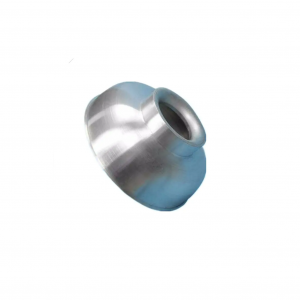

Customized automotive stamping parts

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

How a turbocharger works

The engine exhaust gas's inertial momentum is used by the turbocharger to power the turbine inside the turbine chamber. The coaxial impeller is driven by the turbine. Pressurizing the air inside the cylinder, the impeller moves and compresses the air from the air filter pipe. Both the turbine and the exhaust gas discharge speed rise in tandem with an increase in engine speed. More air is compressed into the cylinder by the impeller. More fuel can be burned because of the increased air pressure and density. The engine's output power can be increased together with the corresponding increase in fuel. Turbochargers can lower pollution and fuel consumption while simultaneously increasing engine output. As a result, they are receiving more attention in contemporary automobiles.

The idea behind a turbocharger is to compress air in order to increase the engine's intake volume and thus boost engine performance. In particular, the turbine in the turbine chamber is propelled by the turbocharger using the inertial momentum of the exhaust gas released from the engine. The coaxial impeller is driven by the turbine. The air from the air filter pipe is compressed, transported, and pressurized by the impeller before entering the cylinder. By raising the air's density and pressure, this procedure not only enhances engine performance but also boosts power production by enabling the engine to burn gasoline more effectively.

The turbocharger design also includes an intercooler, which cools the compressed air down to ambient temperature because the air heats up during compression. The cooler air is denser and serves the purpose of forcing more air into the engine, further improving engine performance. In addition, turbocharging technology also involves some complex components and systems, such as intercoolers, exhaust valves, etc. These components and systems are designed to ensure the effective operation of the turbocharger and the optimization of engine performance.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Company Profile

Ningbo Xinzhe Metal Products Co., Ltd., as a stamping sheet metal supplier in China, specializes in the production of auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, hardware accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tools, Toy accessories, electronic accessories, etc.

Through active communication, we can better understand the target market and provide helpful suggestions to help increase our customers' market share, which is beneficial to both parties. In order to win the trust of our customers, we are committed to providing excellent service and high-quality parts. Build long-term relationships with existing clients and seek out future clients in non-partner countries to facilitate collaboration.

OUR SERVICE

1. Professional R&D team - Our engineers provide unique designs for your products to support your business.

2. Quality Supervision Team - All products are strictly tested before being sent to ensure that all products run well.

3. Efficient logistics team - customized packaging and timely tracking ensure safety until you receive the product.

4. Independent after-sales team-providing timely professional services to customers 24 hours a day.

5. Professional sales team - the most professional knowledge will be shared with you to help you do business better with customers.