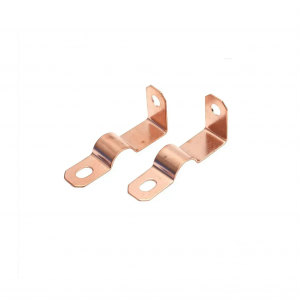

Custom Powder Coated Elevator Straight Angle Bracket

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantages

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. Factory direct supply, more competitive price.

6. Professional, our factory has served the sheet metal processing industry and used laser cutting for more than 10 years.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Powder coating

Powder coating is a surface treatment technology that sprays powdered paint evenly onto the metal surface through electrostatic spraying, and then melts and solidifies the powder by heating to form a strong and durable coating.

Main advantages of powder coating:

Environmental protection- No volatile organic compound (VOC) emissions, environmentally friendly.

Durability- Excellent corrosion resistance and wear resistance.

Aesthetics- Available in a variety of colors and surface effects (such as gloss, matte, texture).

Cost-effectiveness -High paint utilization and efficient coating process.

Powder coating is widely used in the surface treatment of various metal products, mainly including the following fields:

Architecture and decoration

Door and window frames

Guardrails and railings

Building structures

Interior decoration parts

Automotive industry

Body parts

Chassis parts

Interior parts

Engine and mechanical parts

In the elevator industry, powder coating is widely used in the surface treatment of various elevator parts due to its excellent corrosion resistance, wear resistance and aesthetics.

Application examples:

Elevator door panels and frames

Powder coating not only improves corrosion resistance, but also provides a variety of colors and textures to enhance the appearance and design of the elevator.

Elevator guide rails and guides

Provides good lubricity and wear resistance on these parts to ensure smooth operation of the elevator.

Elevator car interiors include car siding, ceiling and elevator handrails

Through powder coating treatment, not only the decorative effect is enhanced, but also the durability is improved.

Elevator button panels and control cabinets

Powder coating provides an antibacterial and wear-resistant surface for these frequently contacted parts, ensuring long-term use.

The application of powder coating technology in the elevator industry has significantly improved the performance and appearance of elevator equipment, while also reducing maintenance costs and increasing service life.

FAQ

Q: Are you a trading company or manufacturer?

A: We are manufacturer.

Q: How to get the quote?

A: Please send your drawings (PDF, stp, igs, step...) to us by email , and tell us the material, surface treatment and quantities, then we will make a quotation to you.

Q:Can I order one or two pieces for testing only?

A: Without a doubt.

Q:Can you manufacture based on the samples?

A: We are able to produce based on your samples.

Q:What's the duration of your delivery time?

A: Depending on the size of the order and the status of the product, 7 to 15 days.

Q:Do you test every item before shipping it out?

A: Before shipping, we do a 100% test.

Q:How can you establish a solid, long-term business relationship?

A:1. To guarantee our clients' benefit, we maintain high standards of quality and competitive pricing;

2. We treat every customer with the utmost friendship and business, regardless of their origins.