Custom metal welding parts

Metal welding is a fabrication (fabrication welding) or sculptural process of joining metals. During the welding process, the work piece and the solder melt or do not melt to form a material-direct joining metal welding parts. During this process, pressure is often also required to join the weldment. There are more than 40 metal welding methods, which are mainly divided into three categories: fusion welding, pressure welding and brazing:

Fusion welding is a method in which the work piece interface is heated to a molten state during the welding process and the welding is completed without pressure.

Pressure welding is to make two work pieces realize interatomic bonding in a solid state under pressure, also known as solid-state welding.

Brazing is to use a metal material with a lower melting point than the work piece as the solder, heat the work piece and the solder to a temperature higher than the melting point of the solder and lower than the melting point of the work piece, use liquid solder to wet the work piece, fill the interface gap and achieve Inter-diffusion between atoms, so as to realize the welding method.

-

High-strength elevator shaft metal parts processing

-

Custom welded oxide elevator bracket with rivet nuts

-

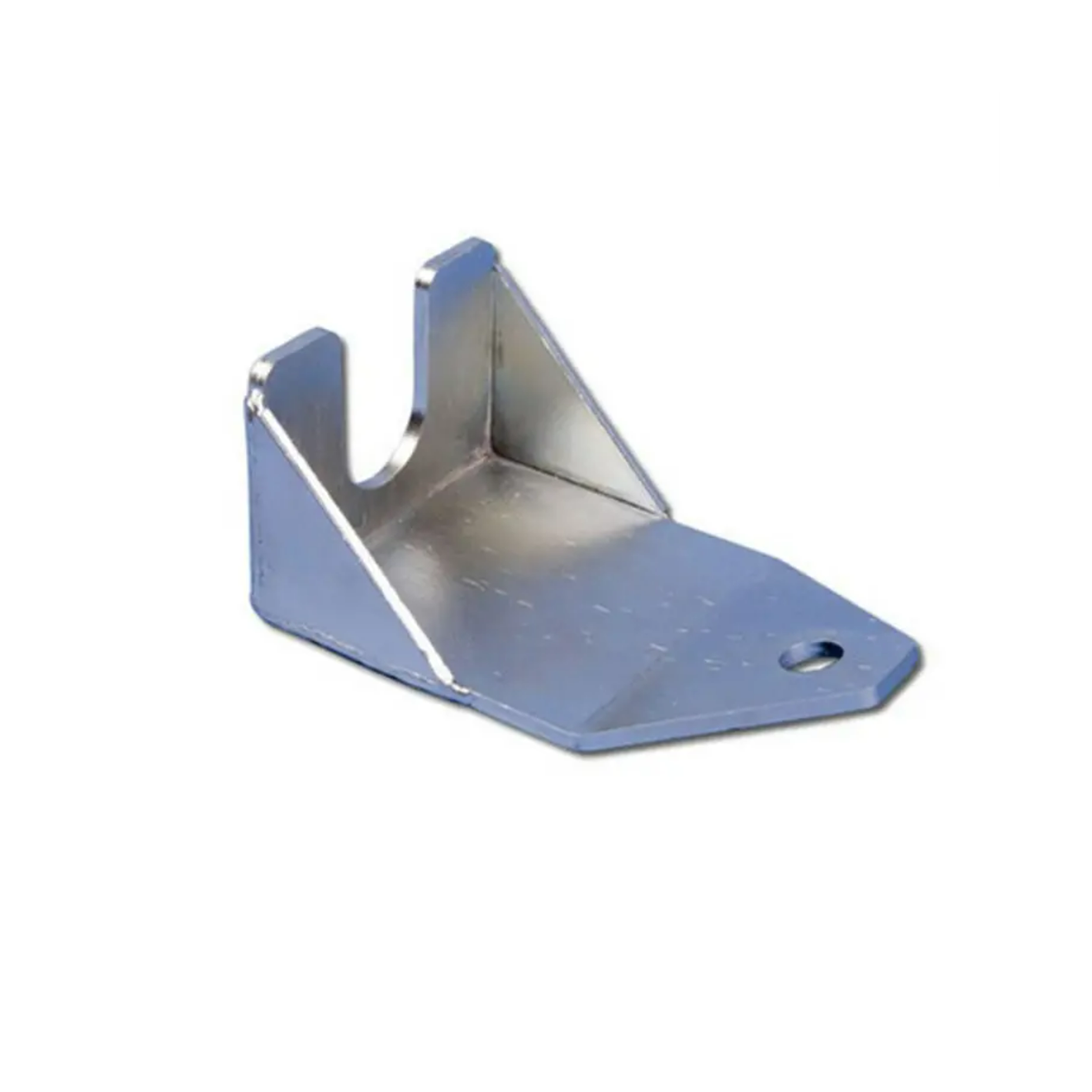

Customized elevator bracket welded galvanized stamping parts

-

Customized galvanized stamping elevator bracket 90 degree angle bracket

-

Customized Q235b Welding Galvanized Stamping Parts For Elevator Bracket

-

Customized Q235B welding galvanized stamping Elevator Brackets Metal Parts

-

Custom Metal Stamping Factory Hardware welding Part

-

Stainless Steel Sheet Metal Stamping Welding Custom Metal Fabrication Tools

-

Customized metal sheet bended welding engineering machinery spare parts

-

Custom high strength Metal stamped welding bracket

-

Customized metal bending and welding parts factory

-

Custom metal Stamped Welded Parts for Tractor