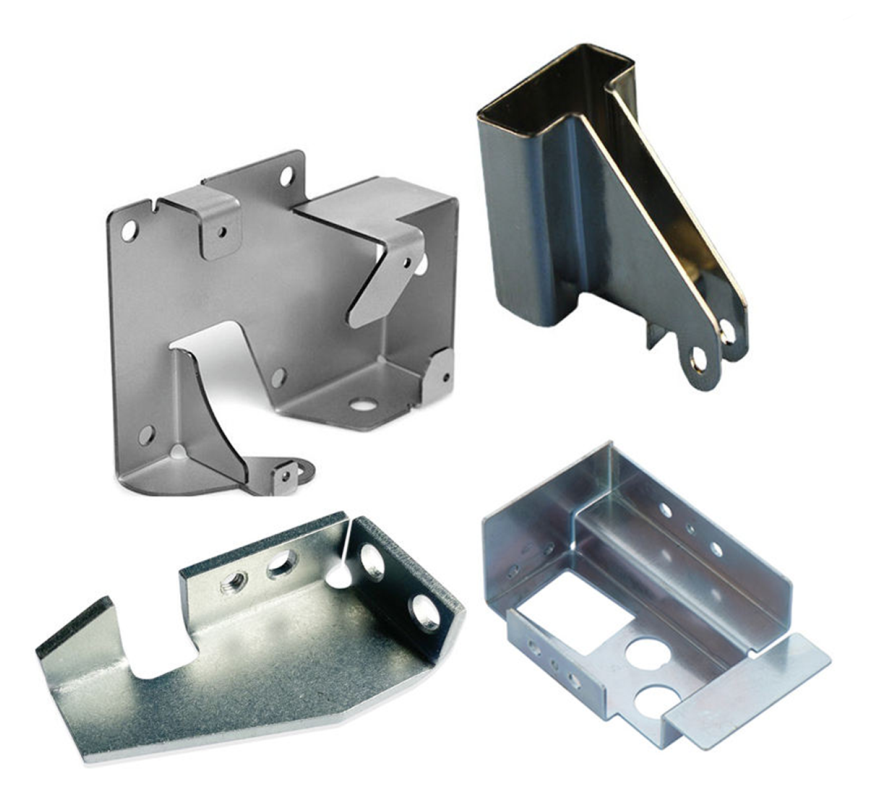

Custom Metal Stamping Service

We look at every product and process from the standpoint of lowest cost material (not to be confused with lowest quality) combined with maximized production systems that can remove as much non-value labor as possible while ensuring that the process can give 100% product quality.

Verify that each item complies with the necessary requirements, tolerances, and surface polish. Monitor the progress of the machining. Our quality control system has received ISO 9001:2015 and ISO 9001:2000 quality system certification.

Since 2016, it has been exporting to other countries while also offering OEM and ODM services. As a result, it has gained the confidence of more than 100 clients both domestically and internationally and developed close working ties with them.

The business employs 30 professionals and technicians and has a 4000㎡ factory.

The workshop has 32 punch presses of various tonnages, the largest of which is 200 tons, and specializes in providing customers with various customized stamping products.

We offer all surface treatments you require to produce a superb finished product, including sandblasting, polishing, anodizing, electroplating, laser etching, and painting.

Company Profile

The 2016-founded Ningbo Xinzhe Metal Products Co., Ltd. has more than 7 years of expertise producing custom metal stamping. Precision stamping and mass manufacture of intricate stamping components are the main emphasis of our facility. It offers creative solutions for your difficult items based on its refined production method and cutting-edge industrial technologies.Over the years, we have been adhering to the business tenet of "survival by quality, development by reputation", and are committed to providing you with high-quality products and high-quality services. With a professional and dedicated design and management team, from product design, mold manufacturing, molding to product assembly, every link and process has been strictly tested and controlled.

The top producer of precise medical equipment stamping parts in China

Medical device stamping is extremely specialized parts created to satisfy the particular requirements of the healthcare sector. These components are made using a stamping method, which uses hydraulic presses to exert intense pressure on metal sheets to shape and deform them into the required shapes and sizes. For the medical equipment they are a part of to operate properly, the precision and accuracy of these components are essential.

Design, prototyping, testing, and serial manufacturing are all steps in the intricate process of medical device stamping. A 3D model of the medical equipment that will be manufactured is created during the design process and utilized to create a prototype. Testing is done on prototypes to make sure they adhere to all requirements.

Our business specializes in producing micro deep drawing stamping and precision stamping, which can effectively ensure the accuracy of medical stamping parts!

Leading producer of auto stamping parts in China

Currently, metal stamping product is employed in many different industries, including those that deal with autos, household appliances, construction, etc. Among these, the metal stamping industry's contribution to automobile stamping is significant.

The capacity to swiftly create a large quantity of components is one of the key benefits of automobile stamping. This is crucial for the automobile sector, as producers turn out tens of thousands of vehicles annually. They can accomplish this fast and effectively with automotive stamping, which lowers costs and boosts production.Another benefit of automobile stampings is their high level of accuracy.

Stamping machines are made to cut and shape metal to the precise measurements needed for each item, guaranteeing that every component is similar to the next. Vehicle reliability and safety depend on this accuracy.

We now have commercial connections with several well-known companies, including Ford and Volkswagen. We are certain that our stamping technology strength can increase clients' marketing competitiveness thanks to our extensive expertise in stamping die design and quality control. Our competent R&D staff can fulfill any special requests from clients. Simply send us a CAD or 3D floor layout, and we'll take care of everything else until your order shows up. You are invited to examine the metal components' quality and our customer service.

China's leading manufacturer of electronic accessories stamping

Xinzhe provides high-quality, cutting-edge components to various customers in the communication field. We are a trusted supplier of various electronic accessories.

To produce high-quality electronic accessories stamping parts, it is first necessary to carry out precise stamping process planning. This includes designing suitable molds, selecting high-quality raw materials, controlling appropriate stamping temperature and pressure, etc. The precision stamping process will ensure product accuracy, reliability and compliance to specifications.

Another key element is total control when cleaning and packaging products. Cleanliness is one of the decisive factors in determining the quality of stamped products for electronic accessories. During the manufacturing process, products are affected by a variety of impurities and contaminants, including oils, oxide layers and dust. Therefore, the product needs to be deeply cleaned and sealed and moisture-proof when packaged.

To sum up, for the production of high-quality electronic accessories stamping products, it is necessary to choose a stamping company with rich experience and technology. Our company should be able to provide a complete set of mature stamping process solutions to ensure that the produced products meet specifications, have high precision and high reliability.