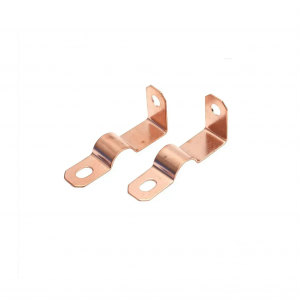

Custom Galvanized Steel Valve Actuator Mounting Brackets

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantages

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. Factory direct supply, more competitive price.

6. Professional, our factory has served the sheet metal processing industry and used laser cutting for more than 10 years.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Design and Manufacturing

Valve actuator mounting brackets are support structures used to fix valve actuators (such as electric, pneumatic or hydraulic actuators) to valves.

These brackets are usually made of strong materials such as stainless steel or carbon steel to ensure their durability and reliability under various operating conditions.

1. Size and shape: The size and shape of the bracket must match the interface of the actuator and the valve to ensure accurate installation.

2. Material selection: Select the appropriate material according to the application environment (such as corrosive environment, high temperature environment, etc.).

3. Structural strength: The bracket needs to have sufficient strength and rigidity to withstand the weight of the actuator and the forces generated during operation.

4. Anti-corrosion treatment: When used in a corrosive environment, the surface of the bracket is usually treated with anti-corrosion treatment, such as galvanizing, spraying, etc.

High-quality galvanized brackets can ensure the correct alignment and firm connection between the actuator and the valve, thereby ensuring accurate control and operation of the valve.

Our service

Every project is unique to us. Your vision directs its evolution, and it is our responsibility to turn this vision into reality. To do this, we make an effort to understand every facet of your project.

As of right now, our group can offer specialized metal stamping services in the following fields:

Stamping progressive in both small and big quantities

Secondary stamping in small batches

In-mold tapping

Secondary/assembly tapping

Forming and processing

Additionally, supply elevator accessories and parts to elevator manufacturers and users.

Accessories for elevator shafts: Provide the many kinds of metal accessories—such as brackets and guide rails—that are needed for the elevator shaft. These add-ons are necessary for elevators to operate safely.

Products such as escalator trusses and ladder guides are essential parts that give escalators structural support and direction, guaranteeing both the stability of the escalators and the security of their users.

In order to collaboratively develop new products and technologies to support the development of the elevator industry, Xinzhe Metal Products Company typically forges strong, long-term working agreements with various elevator manufacturers.

R&D innovation: To satisfy the constantly shifting needs of users and the market, invest continuously in R&D finances and technical forces to foster technological innovation and product upgrades of metal product components and accessories.