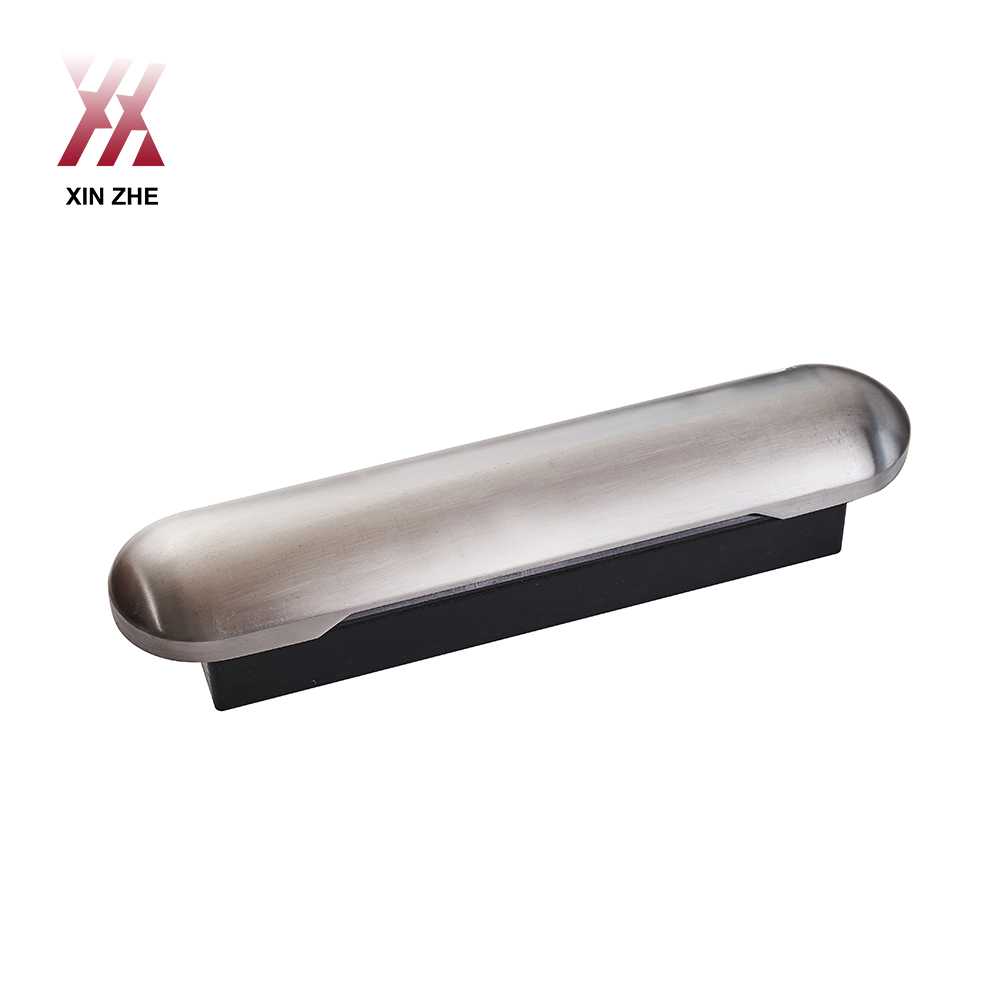

China wholesale Utensils And Cookware Products – Custom stainless steel stamping and bending parts – Xinzhe

China wholesale Utensils And Cookware Products – Custom stainless steel stamping and bending parts – Xinzhe Detail:

Description

Description

Generally speaking, there are two methods of bending stainless steel pipes, one is cold bending method, and the other is hot bending method.( bending stainless steel tubing/ stainless bending)

The first method: cold bending method, this method generally uses a bending machine for multiple roll forming to achieve our bending purpose. However, this method is not perfect. Due to the limited diameter of the steel pipe, the general bending angle is only 1CM-5CM. Furthermore, the curvature is too small, and the diameter of the steel pipe is also very easy to deform.( bending stainless steel sheet/ bending 304 stainless steel sheet/ stainless steel bent plate)

The second method: hot bending method, this method is generally to fill the stainless steel pipe with sand, and then use high temperature to heat-treat and stretch the workpiece. Compared with the cold bending method, this method is the most ideal, but it is not perfect, that is, the processing cost of this method is too high, and it is generally not suitable for large-scale processing.( best stainless steel for sheet metal bending/ stainless tube bender)

Generally speaking, the thicker the steel plate, the greater the bending force we should adjust when adjusting the bending equipment; in addition, under the unit size of stainless steel bending, the greater the tensile capacity of the steel plate, the greater its elongation The smaller the rate, the greater the bending force and bending angle.( bending stainless steel sheet metal/ stainless steel pipe bender)

If the thickness of the stainless steel plate corresponds to the bending radius in the design drawing, then the expanded size of our bent workpiece should be the thickness of the right-angled side plus or minus the double-layer plate, so as to meet the design accuracy requirements. The last point to note is that the greater the yield strength of the stainless steel material, the greater the range of elastic recovery. If the 90-degree angle of the bending part can be obtained, the angle of the pressing knife must be designed to be smaller.( stainless steel bending/ stainless steel tapping)

Frequently asked questions about stainless steel pipes for steel processing:

In our stainless steel pipe bending work, cracks often appear on the surface of the steel pipe. This situation is generally after the steel pipe is stretched and deformed, when it is demoulded, and after impact or vibration stretching deformation. If it is not handled in time, it will be in the It gets bigger after using it for a while. The main reason is that stainless steel has low ductility, high elastic modulus, and large hardening index, and the plastic deformation stage from yielding to cracking after bending is relatively short.( stainless steel threading dies/ best tapping fluid for stainless steel/ tapping screw)

According to the classification of stainless steel, we found that the cold hardening index of austenitic stainless steel is relatively higher. It is a metastable material, and it will undergo phase transformation when deformed, and it is very likely to form a martensitic structure. This structure is very brittle, so it is easy to crack. Generally speaking, there are two methods of bending stainless steel pipes, one is cold bending method, and the other is hot bending method.( drilling and tapping stainless steel/ metal product tapping)

The first method: cold bending method, this method generally uses a bending machine for multiple roll forming to achieve our bending purpose. However, this method is not perfect. Due to the limited diameter of the steel pipe, the general bending angle is only 1CM-5CM. Furthermore, the curvature is too small, and the diameter of the steel pipe is also very easy to deform.( self tapping screws/ self tapping metal screws/ stainless steel self tapping screws)

The second method: hot bending method, this method is generally to fill the stainless steel pipe with sand, and then use high temperature to heat-treat and stretch the workpiece. Compared with the cold bending method, this method is the most ideal, but it is not perfect, that is, the processing cost of this method is too high, and it is generally not suitable for large-scale processing.( self tapping screws for steel/ self tapping sheet metal screws)

Frequently asked questions about stainless steel pipes for steel processing:

In our stainless steel pipe bending work, cracks often appear on the surface of the steel pipe. This situation is generally after the steel pipe is stretched and deformed, when it is demoulded, and after impact or vibration stretching deformation. If it is not handled in time, it will be in the It gets bigger after using it for a while. The main reason is that stainless steel has low ductility, high elastic modulus, and large hardening index, and the plastic deformation stage from yielding to cracking after bending is relatively short.( self tapping bolts for steel/ self tapping screws for aluminum)

According to the classification of stainless steel, we found that the cold hardening index of austenitic stainless steel is relatively higher. It is a metastable material, and it will undergo phase transformation when deformed, and it is very likely to form a martensitic structure. This structure is very brittle, so it is easy to crack.( self tapping screws for metal studs/ countersunk self tapping screws)

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for China wholesale Utensils And Cookware Products – Custom stainless steel stamping and bending parts – Xinzhe , The product will supply to all over the world, such as: Munich, Libya, Thailand, We have been making our products for more than 20 years . Mainly do wholesale , so we have the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we provide good products , but also because of our good after-sale service . We are here waiting for you for your inquiry.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.