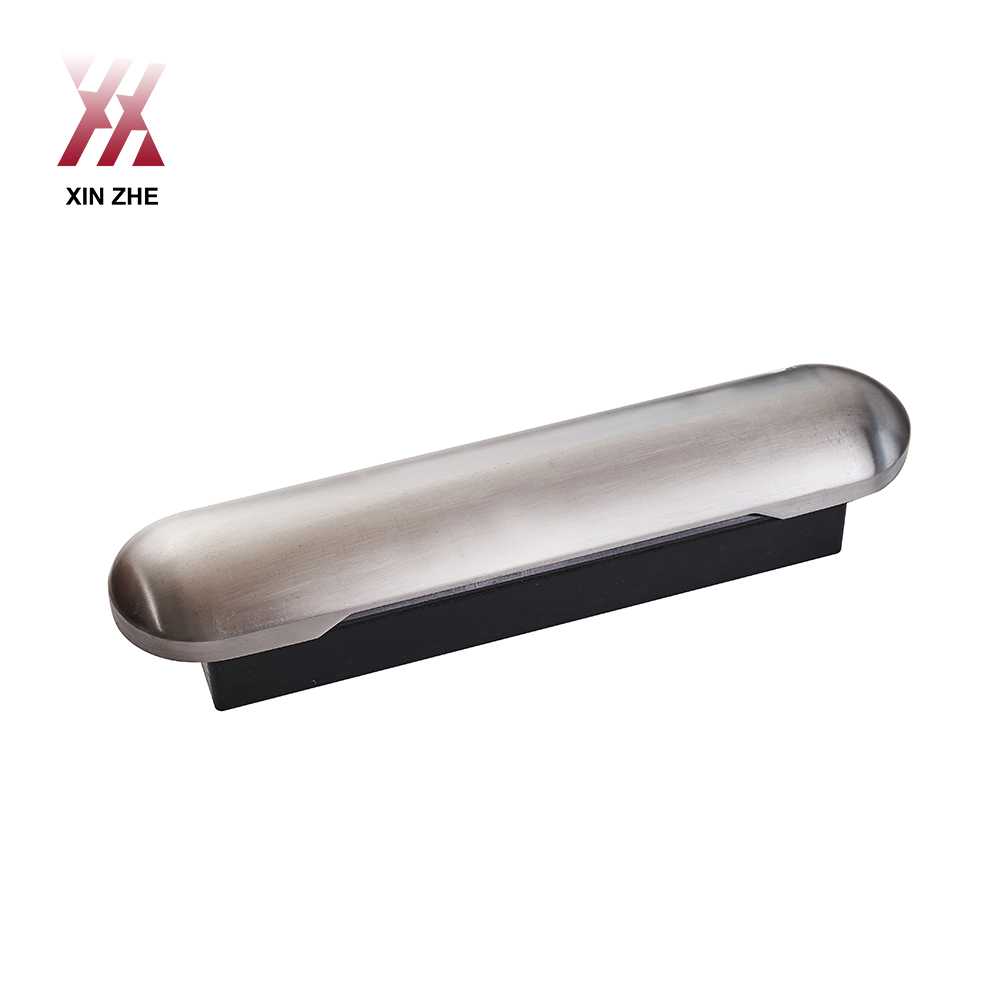

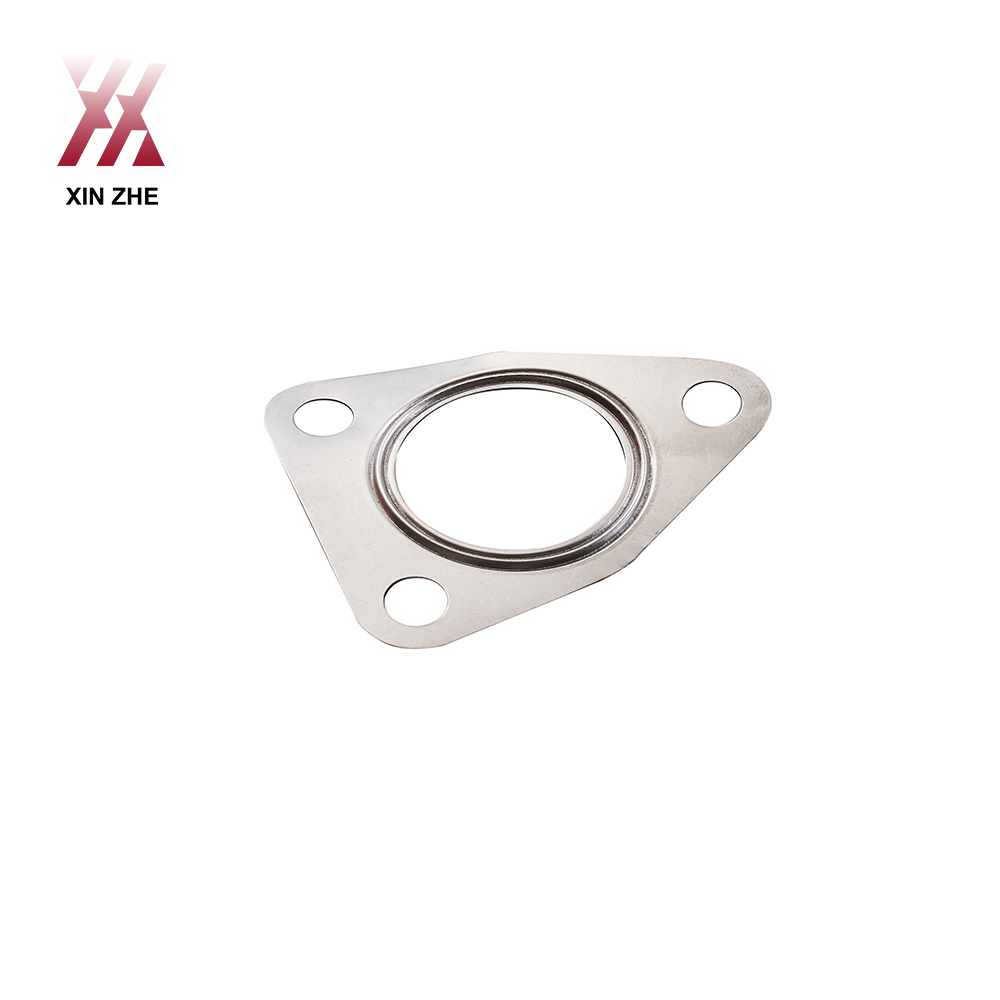

China wholesale Turbocharger Bracket Company – OEM Carbon Steel Precision Sheet Metal Stamping Parts Factory – Xinzhe

China wholesale Turbocharger Bracket Company – OEM Carbon Steel Precision Sheet Metal Stamping Parts Factory – Xinzhe Detail:

Description

FAQ

1. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

2. How about the lead time?

Generally, 2-3 weeks for samples, 3-4 weeks for mass production.

3. How do you control the quality?

(1)Material inspection–Check the material surface and roughly dimension.

(2)Production first inspection–To ensure the critical dimension in mass production.

(3)Sampling inspection–Check the quality before sending to the warehouse.

(4)Pre-shipment inspection–100% inspected by QC assistants before shipment.

4. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Stamping is the forming process of the workpiece(stamping part) by applying external force to the plate,strip,pipe and profile by press and die to produce plastic deformation or separation.stamping and forging belong to forming procseeing (or pressure machining).the stamping materials are mainly hot rolled and cold-rolled steel plates and steel strips.

Stamping is the production technology of product parts with a certain shape, size and performance by using the power of conventional or special stamping equipment to make the sheet metal directly deformed and deformed in the mold.sheet metal,mold and equipment are the three elements of stamping process.according to the stamping temperature,it can be divided into hot stamping and cold stamping.the former is suitable for sheet metal processing with high deformation resistance and poor plasticity,while the latter is carried out at room temperature,which is a common stamping method for thin plates.it is one of the main methods of metal plastic processing(or pressure machining),and also belongs to material forming engineering technology.

Product detail pictures:

Related Product Guide:

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for China wholesale Turbocharger Bracket Company – OEM Carbon Steel Precision Sheet Metal Stamping Parts Factory – Xinzhe , The product will supply to all over the world, such as: Argentina, Somalia, Morocco, By adhering to the principle of human oriented, winning by quality, our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly