High-Quality China Elevator Rail Bracket & Shaft Component Supplier

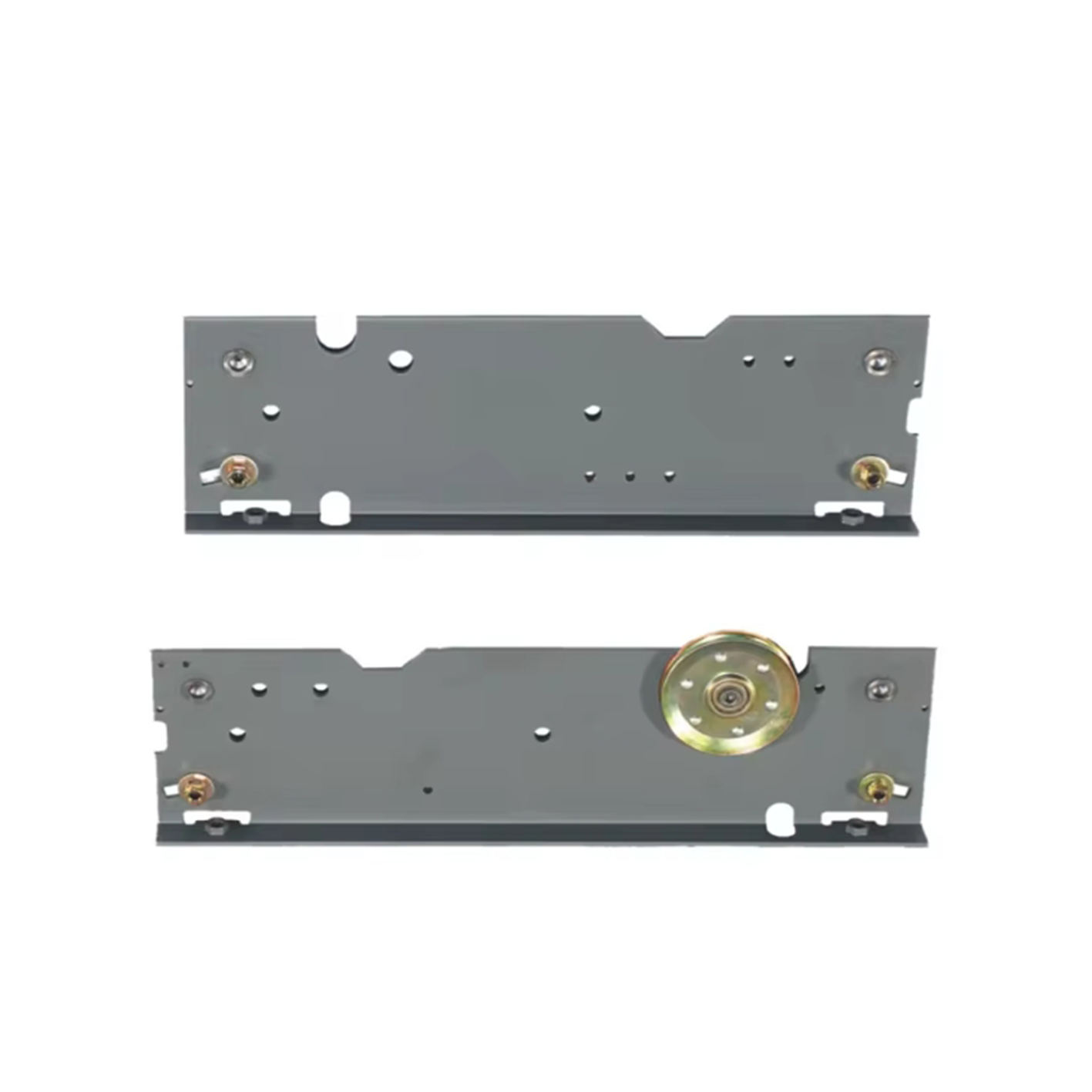

When it comes to elevator parts, I know how important reliability and quality are. Our China Elevator Rail Bracket and Shaft Component Rail Bracket are designed for maximum strength and durability, ensuring your elevators operate smoothly and safely. Crafted with high-quality materials, these components have been rigorously tested to withstand the rigors of everyday use. As a supplier committed to excellence, I focus on providing you with these essential parts that meet international standards. Every rail bracket is precision-engineered, guaranteeing a perfect fit and long-lasting performance. Whether you're upgrading existing systems or working on new projects, you can trust our brackets to deliver superior results. By choosing our products, you're investing in quality that benefits your business and your customers. Let's enhance your elevator systems together! For more information or to place an order, just reach out.

China Elevator Rail Bracket and Shaft Component Rail Bracket Industry Giant Sets the Industry Standard

In the competitive landscape of the elevator industry, the significance of high-quality rail brackets and shaft components cannot be overstated. As the demand for innovative and reliable elevator systems continues to grow globally, key players in the manufacturing sector are stepping forward to set new industry standards. One company, recognized as a giant in this domain, has leveraged its extensive expertise to enhance the quality, safety, and efficiency of elevator rail brackets and components. With a commitment to rigorous testing and adherence to international standards, this industry leader has pioneered advancements in material technology and precision engineering. Their products not only meet but exceed the expectations of global procurement buyers looking for durability and performance. By adopting cutting-edge manufacturing processes, this company ensures that their rail brackets provide superior support and stability, essential for the safe operation of elevators. Moreover, sustainability is at the forefront of modern manufacturing practices. The industry giant emphasizes eco-friendly production methods, reducing waste and energy consumption while delivering high-quality components. As global buyers prioritize sustainable sourcing, partnering with a company that aligns with these values can be a decisive factor in enhancing market competitiveness. By consistently innovating and striving for excellence, this manufacturing leader is poised to shape the future of the elevator rail bracket industry.

China Elevator Rail Bracket and Shaft Component Rail Bracket Industry Giant Sets the Industry Standard

| Dimension | Specification | Material Type | Standard Compliance | Application Area |

|---|---|---|---|---|

| 2000 mm x 100 mm | A2.5 | Steel | ISO 9001 | Residential Elevators |

| 2500 mm x 120 mm | A3.0 | Aluminum | CE Marking | Commercial Elevators |

| 3000 mm x 150 mm | A4.0 | Stainless Steel | EN 81-20 | Industrial Elevators |

| 1800 mm x 80 mm | A1.0 | Composite Material | ASME A17.1 | Freight Elevators |

| 3500 mm x 200 mm | A5.0 | Carbon Fiber | GB 7588 | Service Elevators |

Related Products