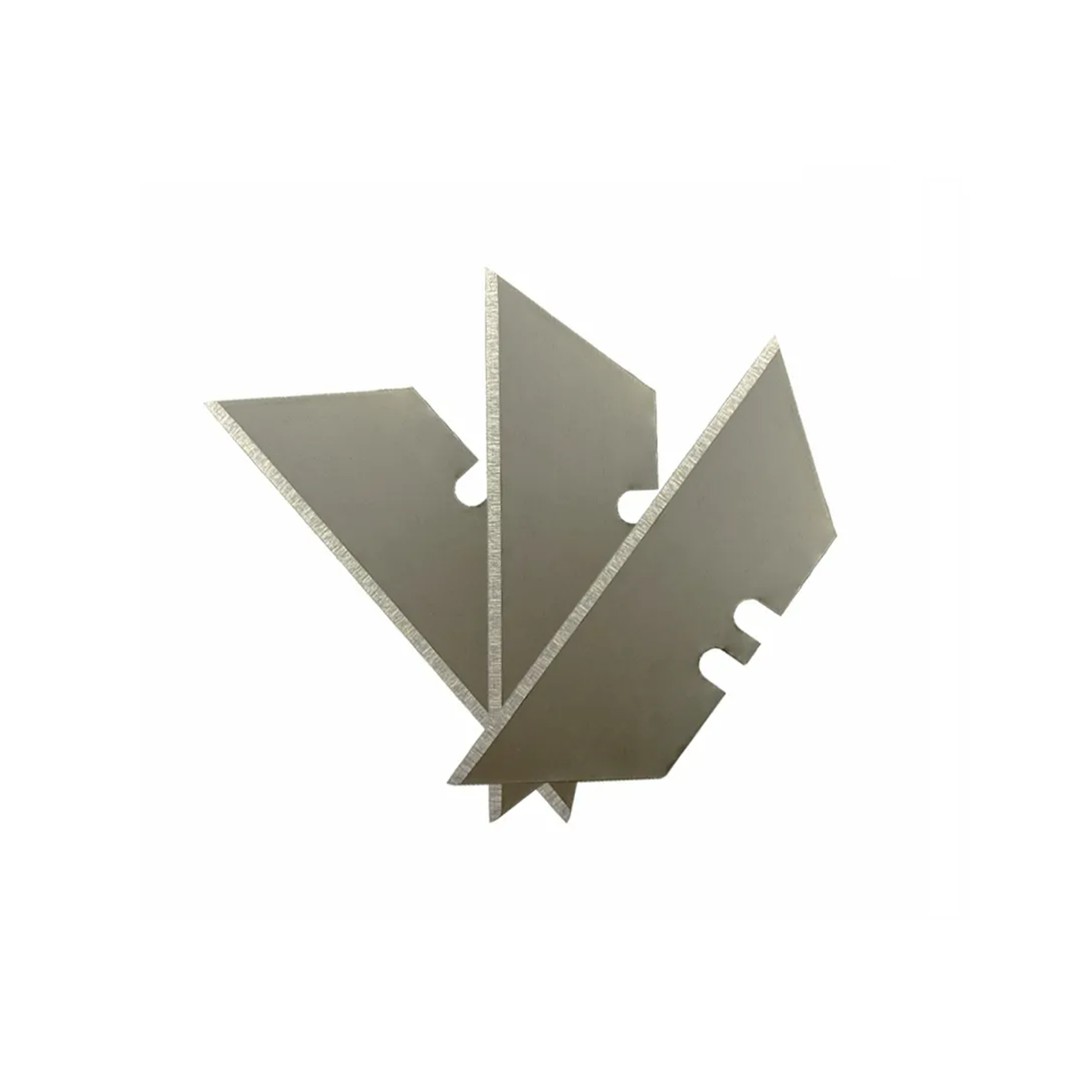

Best extreme sharp T style blades

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Stainless steel stamping

Stainless steel stamping operations include:

blanking

bending

metal forming

punching

casting

Short run production and prototyping

Stainless steel disc stamping

Characteristics of Stamped Stainless Steel Parts

Features and benefits of stainless steel include:

Fire and heat resistance: Stainless steels containing large amounts of chromium and nickel are particularly resistant to thermal stress.

Aesthetics: Consumers appreciate the clean, modern look of stainless steel, which can also be electropolished to improve the finish.

Long-term cost-effectiveness: While stainless steel may cost more initially, it can last for decades without quality or cosmetic damage.

Hygiene: Some stainless steel alloys are trusted by the pharmaceutical and food and beverage industries due to their ease of cleaning and are also considered food grade.

Sustainability: Stainless steel is considered one of the most sustainable alloy options, making it ideal for green manufacturing methods.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Quality system

All of our facilities are ISO 9001 certified. In addition, Xinzhe has extensive experience in quality control systems and processes across many industries and specific applications.

Production Parts Approval Process

Control Plan

Failure Mode and Effects Analysis (FMEA)

Measurement Systems Analysis (MSA)

initial process study

Statistical Process Control (SPC)

Our quality laboratory also builds calibration systems ranging from CMMs and optical comparators to hardness testing. Contact us to learn more.

OUR SERVICE

1. Professional R&D team - Our engineers provide unique designs for your products to support your business.

2. Quality Supervision Team - All products are strictly tested before being sent to ensure that all products run well.

3. Efficient logistics team - customized packaging and timely tracking ensure safety until you receive the product.

4. Independent after-sales team-providing timely professional services to customers 24 hours a day.

5. Professional sales team - the most professional knowledge will be shared with you to help you do business better with customers.