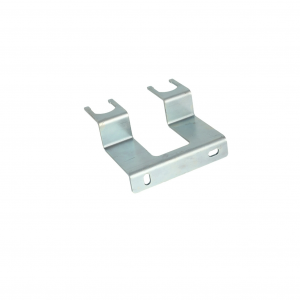

Best Deals Car Sheet Metal Brackets Metal Parts

Description

| Product Type | customized product | |||||||||||

| One-Stop Service | Mold development and design-submit samples-batch production-inspection-surface treatment-packaging-delivery. | |||||||||||

| Process | stamping,bending,deep drawing,sheet metal fabrication,welding,laser cutting etc. | |||||||||||

| Materials | carbon steel,stainless steel,aluminum,copper,galvanized steel etc. | |||||||||||

| Dimensions | according to customer's drawings or samples. | |||||||||||

| Finish | Spray painting, electroplating, hot-dip galvanizing, powder coating, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Application Area | Auto parts, agricultural machinery parts, engineering machinery parts, construction engineering parts, garden accessories, environmentally friendly machinery parts, ship parts, aviation parts, pipe fittings, hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. More than 10 years of overseas trade expertise.

2. Provide one-stop service from mold design to product delivery.

3. Fast delivery time, about 30-40 days. In stock within one week.

4. Strict quality management and process control (ISO certified manufacturer and factory).

5. More reasonable prices.

6. Professional, our factory has more than 10 years of history in the field of metal stamping sheet metal.

Quality management

Vickers hardness instrument.

Profile measuring instrument.

Spectrograph instrument.

Three coordinate instrument.

Shipment Picture

Production Process

01. Mold design

02. Mould Processing

03. Wire cutting processing

04. Mold heat treatment

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Stainless steel features

The most common alloy in the austenitic series, 304 stainless steel is the workhorse of the 300 SS family and is used to create stamped and machined parts in corrosive and high-heat applications. In addition to car parts, engineering equipment parts, construction engineering parts, hardware parts, electrical products, etc., Xinzhe Metal Stamping Parts also manufactures and provides 304 stainless steel stamping parts.

Because 304 stainless steel is so easily bent and stamped into most shapes, it is most frequently used for metal forming, welding, and custom stamping.

Features of 304 stainless steel stamping

demonstrates great strength and resistance against corrosion.

Resistance to high temperatures

auto parts

Stamping is highly advantageous for the automotive industry, which has specific needs and requirements, thanks to several key advantages:

1. Mass production efficiency: Making automobiles typically entails making a lot of the same parts.

2. Cost-effective production: The technique can swiftly produce large quantities of car parts when the stamping mold is mounted, which improves cost-effectiveness.

3. Material versatility: Stamping can be done using a wide range of materials, including popular automotive industry metals and alloys.

4. Production of complex parts: Complex parts with particular shapes and properties are frequently found in vehicles. Complex items including body panels, brackets, and structural elements can be produced by stamping.

5. High accuracy and consistency: The automotive assembly's overall quality is enhanced by the use of precision molds and presses, which guarantee that every stamped item satisfies stringent dimensional requirements.

Each car is broken down into numerous parts, and each part requires a different manufacturing process. However, metal stamping technology is an indispensable and cost-effective solution. The process can produce a variety of spare parts, including:

Body covering parts: such as bumpers, hoods, doors, instrument panels, fenders and trunk lids, etc.

Chassis components: such as brackets, fuel tanks, brake housings, clutch plates, frame components and reinforcements, etc.

Interior parts: including seat frames, panels and trim.

Engine parts: such as valve cover, bracket.

Suspension components: such as control arms, brackets and links.

Mechanical parts: pin holes in the crankshaft connecting rod mechanism, camshaft bearing seat holes and gear chambers, etc.

Electrical parts: generator rotor bearings, brush holders, connectors, terminals and shielding layers, etc.

Fasteners: various types of washers, clips, etc.

Decorative and decorative elements: badges, emblems, decorative pieces, etc.